Precast composite system elements ensure fully insulated building envelopes

The RappAutarkPlusHaus system is a state-of-the-art building system whose envelope meets the requirements of the German passive house standard. This system relies on industrial production, consumes only minimal amounts of materials and energy, and incurs low construction costs while conforming to enhanced soundproofing and heat insulation standards.

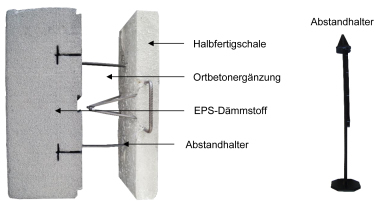

The design includes a lightweight concrete structure on its outside, to which an insulation system is attached. The integrated insulation material acts as permanent formwork and is merged with the concrete layer in the industrial production process at the precast plant. This setup incurs low operating costs and reduces energy consumption; it is no longer necessary to heat the vibration/tilt table.

Integrated solar heating makes it possible to efficiently utilize solar energy for generating hot water while also providing building-integrated, in-wall radiant heating linked to a PV system. The RappAutarkPlusHaus elements are prefabricated industrially and tailored to the client’s requirements. They are then incorporated into the system of walls, floors and ceilings on the job site directly from the delivery vehicle, ensuring that no thermal bridges are created. The Rapp system is suitable for any conceivable building layout.

Features of the RappAutarkPlusHaus system

Compared to conventional construction methods, using custom precast composite system elements (Rapp building system) for fully insulated building envelopes in residential and commercial construction brings about a number of benefits while ensuring at least the same degree of planning and design freedom, namely reduced land use and optimal plot utilization through more slender structural components, an increased share of weather-independent factory production, shortened (shell) construction times, enhanced safety at the workplace, lower production and financing costs, material- and resource-saving construction thanks to smaller element thicknesses, more effective soundproofing created by the resolved cross-section of the component, a more comfortable indoor climate, simplified permitting procedures, and many more.

Production and assembly process

The precast elements are factory-produced in a horizontal position. When the concrete has set, the elements are moved into a vertical position on tilt/turn tables without being subjected to bending loads, lifted from the perimeter formwork, and put to storage for subsequent hardening. Trucks are used to transport the finished external wall elements to the construction site in a vertical arrangement, whereas the roof and floor components are layered horizontally for transport purposes.

The individual elements are lifted into position using a crane and placed on the foundations and floor slabs on joints consisting of a blend of conventional (Class III) and adhesive mortar (such as Compakta or similar brands). In addition, shear bolts measuring 12 mm in diameter are drilled into the joints connecting the individual elements with the foundation or the floor slab, and grouted. During the assembly period, the elements are connected to the floor slab using diagonal supports providing the required resistance to compression and tension.

The roof element is placed on the precast wall elements having a 30° slope corresponding to the roof pitch and then fastened by anchoring to the element joint reinforcement. A cast-in-place infill is subsequently placed on the wall elements.

The innovative aspect of this product is that only two tongue-and-groove ribbed forms designed for special concrete measuring 1000 × 1000 × 180 mm (L × W × T) are produced at the insulation factory. These tongue-and-groove forms are placed individually on vibration/tilt tables at the precast plant in accordance with the shop drawings. In the next step, standard reinforcing mesh is inserted into the custom form in accordance with the structural specification, and the concrete is poured into the form (again as required by the structural specification), and compacted.

Work packages for project workflows were developed and planned as part of the project entitled “EnRapid: Development of a system of prefabricated external wall elements conforming to climate-neutral building standards”.

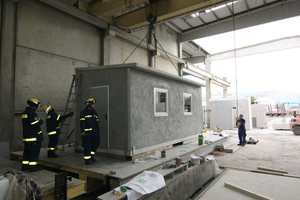

Show house highlights project features

On tilt/turn tables, the elements are completed as follows (bottom to top):

Tongue-and-groove ribbed form designed for special concrete acting as permanent formwork (Resol WLG 021 with cavities for structural concrete frameworks as specified)

Window edge formwork in the insulation area

Carbon textile reinforcement in accordance with the structural specification

Building services/utilities level

Carbon-reinforced concrete supports and frameworks in accordance with the structural specification

Component-integrated clay building panel/render

In-wall radiant heating linked to PV system (alternatively, Carbon-4 with PV link).

Production of the elements at the precast plant

The selected elements are produced at the precast plant and then installed on the job site directly from an 80-ton mobile crane. Installation takes place from basement to roof for envelopes of buildings with up to seven stories, while always making sure that no thermal bridges are created.

Besides Rapp heading the consortium, several other entities act as project partners, including the general contractor, the electrical and solar company, the insulation supplier, the precast plant, the window manufacturer, and the Institute of Concrete Construction at Leipzig University of Applied Sciences chaired by Prof. Dr.-Ing. Klaus Holschemacher.

As early as 1986, Betonwerk Heinrich Hachmeister Andernach GmbH produced the first Rapp elements for a five-family house, which was granted pilot project status and received state and federal funding, and delivered them to Brilon-Alme.

Inventor Albert Bruno Rapp explains: “A prefabricated molded insulation part is, as it were, fused as permanent formwork with the structural components at the precast plant. This saves approximately 40% of raw materials and 43% of primary energy – starting with cement production and ending with the completed project. Therefore, the precast composite building system elements are already supplied with the insulation integrated into the building components, which also reduces construction time by about 50% while gaining additional living space.”

Precast partners for US pilot project sought

In an interview with BFT editorial staff, company owner Albert Bruno Rapp had the following to say regarding further prospects for marketing the system: “Not least as a result of globalization, new products are gaining an increasing share in both the local and the international markets. For instance, in the United States, a new company is currently being established; my ‘Sogines’ building technology prefabricated construction brand will be integrated into this entity. Initial residential and commercial construction projects using the Rapp system have already reached the design and sales stage, and political decision-makers and entrepreneurs show increased interest in the system. Further industry partners that are part of this endeavor are the Eurobaustoff Group based in Karlsruhe, Bauen + Leben in Krefeld, Brenner & Klaudt Baustoffhandel in Bonn, and Sethi Group as the sponsor and prime investor.”

“When implementing our sales concept, it will be crucial to engage interested stakeholders such as precast producers manufacturing innovative products including carbon-reinforced concrete or ribbed forms for special concrete, as well as architects, builders, general contractors, property developers, and other licensees. Specifically for the US market, the Rapp system opens up the opportunity to create affordable housing on a large scale. For instance, clients or owners can install the Rapp building envelope and non-load-bearing internal walls on their own, fully in line with their requirements and specifications.”

“For this reason, we are currently seeking German precast producers willing to engage in completing a pilot project using the Rapp system in the United States, i.e. to transfer the Rapp technology including the structural design and engineering portion,” Rapp concluded.