Priamos by GTSdata - Experiences with

modern ERP software to optimize processes

Priamos by GTSdata aims to not only create a digital network between machines and individual processes but to also enable their digital integration into a comprehensive company network with connectors to the entire outside world. The following renowned Priamos users describe their priorities, goals and experiences made in optimizing their processes.

Priamos by GTSdata aims to not only create a digital network between machines and individual processes but to also enable their digital integration into a comprehensive company network with connectors to the entire outside world. The following renowned Priamos users describe their priorities, goals and experiences made in optimizing their processes.

1 Gilne: Two years of Industry 4.0 in a new smart factory

Since the summer of 2015, the Priamos ERP/PPC system in operation at Gilne GmbH has been tasked with supporting, controlling and monitoring numerous separate processes in administration, production, shipping and follow-up support.

In 2018, the specifications for Gilne’s new concrete plant in the Westphalian town of Ibbenbüren-Uffeln were based on the requirements of a smart factory with “just-in-time” philosophy, paperless production, the use of intelligent software systems, and plants with the highest technically realizable degree of digitization.

Two years ago, the Priamos system by GTSdata was therefore expanded with unique, efficient new software modules that have proven to be extraordinarily successful.

To use the software system and data, robust tablet computers with wireless LAN and touchscreen were installed, in addition to the standard PCs and notebook computers, in particular in the different departments in Production. Large screens for displaying layout, formwork and reinforcement plans were installed in the production areas. The entire system operates in “real-time mode”, meaning that all relevant changes made to a product are immediately available online to all departments.

Some relevant examples:

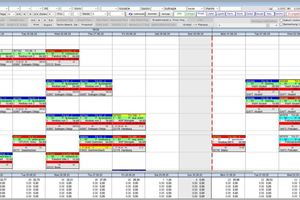

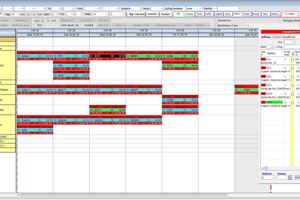

GANTT chart as “control center” for scheduling production and delivery in Production Planning (Fig. 1)

Colored notes in each node pertaining to the order, planning/production status (milestone), and warning color in the case of productions critical due to, for example, missing clearances or embedded parts, or due to the missing report of completion of formwork or reinforcement.

ToDo for CNC, Reinforcement Machines 1 and 2, Formwork Production, Crane and Mixing Tower departments

For each major feature or activity, department-specific milestones are available with start and end dates. Each department (e.g. Reinforcement Production, Formwork Production, or Crane) has its own customized program and can only see its own products or activities, both current and in the pre-planning stage.

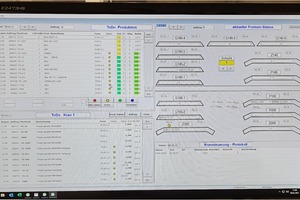

Crane control (Fig. 2)

For the integration of crane control, all crane approach coordinates (mixing tower, molds, reinforcement storage, turning stations etc.) were entered in the Priamos software. The crane’s Siemens PLC is directly provided with the respective approach coordinates and started as soon as an approach point (such as Reinforcement 1) has been selected in Priamos.

Signal lights

As an additional visual source of information, two radio-controlled signal lights with four colors (yellow, red, green, blue) are installed on each dual-use mold. Different color combinations are switched in Priamos automatically in connection with the respective status/milestone of the product. The lights are additionally displayed in the software as color dots for each product, indicating the current status.

Examples of process control for a specific product

If, for example, Formwork Production reports the basic design as completed, the crane operator also receives a status message from Formwork Production via the tablet computer, requesting him to retrieve the reinforcement produced for the product from reinforcement storage and to place it in the formwork. With the “formwork completed” status, a request for concrete delivery is automatically transmitted to the crane. The crane operator uses his tablet computer to transmit the concrete quantity and formulation stored in Priamos to the integrated control system of the mixing tower. Collection of the concrete and approach of the mold are also effected via this control system.

The milestones and signal light are switched accordingly.

Integrated concrete temperature measurement by

means of “Concremote”

After smoothing the concrete, a temperature sensor is placed on the concrete surface and activated via the tablet computer and the Priamos software. The current measured values are imported into the Priamos monitoring system via web service. When the specified degree of hardening has been reached, the signal light is switched, the milestones are changed, the display is updated, and follow-up activities are initiated, all in an automated process.

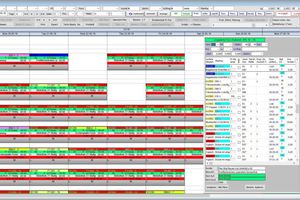

Process monitoring per day and shift in Priamos

This display can be used to permanently display and monitor all current processes with a status related to the molds and the main crane (Fig. 3).

Additional relevant features via tablet computer

Storage via tablet computer with barcode scanning

Loading via barcode, photos of loading process, and printing of delivery bill

Logistics and delivery scheduling using a GANTT chart

2 Max Bögl: Efficient project planning and realization

Priamos has been successfully used as the central ERP system for all precast concrete plants of the Max Bögl group of companies for almost 20 years.

Project management with rough/actual planning,

reservations and 3D integration

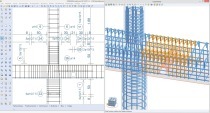

In 2018, the software system was significantly expanded and refined in terms BIM and 3D integration. These modules permit order items (BoQ items) detailed in construction stages to be divided among production facilities, molds and formwork stations, as rough and actual planning, including automatic due date calculation via variance in days per milestones for the different activities and departments.

3D integration using GANTT charts as central

planning control tool

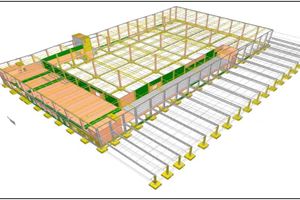

A newly developed permanent exchange of data between the 3D visualization data of a project and the Priamos planning data provides highly professional support in terms of assembly planning and visual progress monitoring for both individual items and the entire project (Fig. 4).

The different departments make highly specific and efficient use of the planning data as due dates, PDF plans, materials and standard times are available in detail and selectable for all departments.

Individual departments, such as formwork production, can efficiently schedule and map the formwork design for each production item over several days including time and staff requirements.

Reinforcement for rough and actual planning

Different charts with separate access rights and project assignments are available as internal and external planning tools, for example, for subcontractors with online access.

Additional planning features:

Collision checks during due date planning

Staff scheduling via integrated staff calendars

Planning assembly via the 3D model

The assembly sequence of the individual items can be planned very efficiently via the visual representation of a project. A special program for visual 3D representation was incorporated, which is also capable of reading and storing projects in IFC format. The items are marked in the desired assembly sequence in the 3D model, color-coded as a result, registered in the 3D model, and transferred directly to Priamos. The schedule including team assignment is immediately visible in the Priamos assembly chart.

Status monitoring via the 3D model

All relevant milestone/status changes for a production item in Priamos are automatically transferred to and stored in the 3D model. Each display/visualization of the 3D model shows all items including their current color-coded status. Depending on the level of authorization, the 3D model can be displayed in any location (e.g. production planning, production, building site, project manager, client etc.) with a network connection (Fig. 5).

3 VETRA: Modern project, logistics and resource planning

Vetra Betonfertigteilwerke GmbH, a subsidiary company of Holcim Deutschland, has been using Priamos for the production and sales of precast floor slabs, double walls and structural precast elements for more than 20 years, operating it as an ERP system at several production plants and with a central IT system. Priamos has been continuously modernized in line with technological developments.

Two years ago, the Greten precast plant in Essen/Oldenburg was acquired by Holcim and assigned to be part of the Vetra plants. This was followed by further digitization of the processes at Holcim’s precast concrete plants in the Netherlands and Germany. The first step was to consistently use existing software modules to increase the efficiency of numerous processes in administration, production and shipment. Parallel steps included the successful introduction of new software modules for rough and actual planning in production, reservations, and the creation of new modules for central cross-national project planning, construction time planning, delivery logistics planning and draftsmen resource management.

Actual construction time schedule per project/

order, construction stage and product

The current actual production items are displayed for each order including their current milestone and time bar. The length of the time bar is generated automatically via the oldest and most recent dates.

Coordinating production and assembly planning

with the client

All individual due dates agreed with the client, from planning to delivery/assembly, are added to a project and can be visualized on a chart as time bars with notes included in the upper section.

Central draftsmen resource planning

The draftsmen independently link plan items from one of the plant pools with their name, as indicated in the chart, and the start date of drawing. The draftsman reports completion by entering the respective milestone. This principle created a new level of quality in the currency and status of the order data, as well as in total and individual capacity utilization.

CONTACT

Gilne GmbH

Herr Matthias Neyer (Geschäftsführer)

Querenbergstr. 1-4

49497 Mettingen/Germany

+49 5452 934 721

Max Bögl GmbH & Co. KG / Fertigteilwerk Hamminkeln

Herr Holger Urselmans (Leiter Produktionssteuerung)

Max-Bögl-Str. 1

92369 Sengenthal/Germany

+49 9181 909-11724

Vetra Betonfertigteilwerke GmbH

Herr Alexander Rüwe (IT-Manager)

Industriestr. 5

26802 Neermoor/Germany

+49 5434 944068

GTSdata GmbH & Co. KG

Herr Herbert Fehlauer (Geschäftsführer)

Zinngießerstr. 12

31789 Hameln/Germany

+49 5151 107380