Max Bögl precast concrete plants provided with new ERP software version

The Max Bögl group of companies has been using the Priamos ERP system of GTSdata GmbH & Co. KG at all precast concrete plants for more than 20 years now. In parallel to the fast-paced international development of software, Priamos is also developed continuously and adapted to the growing requirements in terms of technology and functions.

Following comprehensive tests of the numerous new software components, the new Priamos version 2020 was implemented in all plants as central system for up to 150 users in the summer of 2022 with great success. All previous processing functions, lists, special programs and specific adaptations of the prior version were transferred to Priamos 2020.

A lot of new solutions were developed for the new version; on the one hand, they turn Priamos in the new version 2020 into an even more comprehensive and more efficient product which, on the other hand, meets international standards in terms of quality regarding installation, updates and error recovery. The adoption of the essential features minimized the effort required for installation and training of users, since many new operating elements are also standardized and therefore mostly self-explanatory. The modern individual setting of user-related calls as "favorites" via icons makes operation and data processing even more efficient.

Future-oriented software development

The following technological and professional requirements can be met so as to ensure a future-oriented software developments, examples are:

- Deployment optionally under a normal desktop environment with/without MS terminal server, VMware, Citrix;

- Creation and integration of Web/Internet apps;

- Web services for an unlimited data exchange among different systems, for example;

- Internet customer portal;

- Use of mobile devices (notebooks, smartphones, tablet PCs, etc.) with and without permanent network/WLAN connection;

- If required, conversion of existing online programs as Web/Internet programs for an extended use on tablet PCs and smartphones;

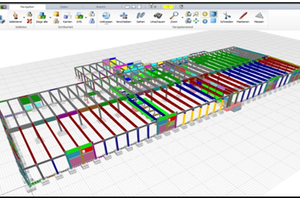

- Priamos industry 4.0 software (with integration of machine control systems such as reinforcement, CNC, crane, mixing tower, etc.);

- Use of the current Oracle database version.

The modern look and feel as well as the existing features of Priamos for supporting a high-quality production and a smooth project process in everyday practice are particularly important for the user:

- Permanent availability of all current status information around the projects and their single items for all departments, from the quotation with calculation up to assembly;

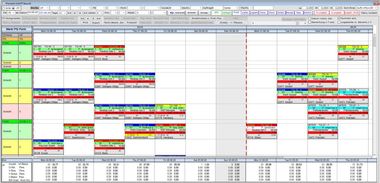

- On-screen data retrieval in various views (multiple, in parallel or ready in the background);

- Display of different parallel views simultaneously on several monitors;

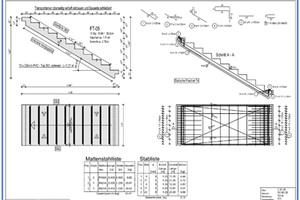

- Archiving of plans and project information of any kind and source in Priamos and whose supporting display and use in all relevant processing programs, including production and assembly;

- One's own compilation of favored program call ups for an efficient daily work;

- Individual setting of additional functions, menus or displays that can be shown/hidden by the user via pin icons (pop-ups);

- Automated exchange and alignment of data among the various integrated systems (BIM, CAD, iTwo, master computer, graphic 3D mold assignment, production status message, loading with scanner, SAP system, etc.);

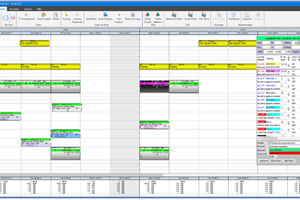

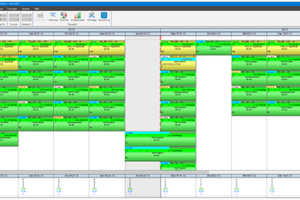

- Integration of new Gantt charts for an additional visualization and digitization of individual processes within the overall planning system, with previous display variants for the various departments.

Cooperation with all Bögl departments

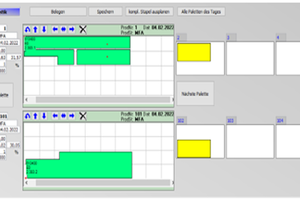

The large number of individual functions were developed in close cooperation with the departments at Bögl and are used every day as a central control module with high efficiency. This include the simultaneous or individual display of rough, detailed and reservations, with access to 3D BIM data and archived plans. A selection or overall view of deadlines as information node for the individual work areas, e. g., preliminary design, approval, reinforcement, cage, formwork, concrete placement, delivery, assembly are possible. Each node comprises a lot of relevant extra information highlighted in color, such as feedbacks from the production, material availability or critical deadlines in traffic light colors. In addition, a pop-up of the unscheduled items is shown for their planning in production, delivery and assembly providing various features (e. g. by means of drag & drop using the mouse or by means of planning parameters for series planning, etc.).

On the basis of these existing, progressive and modern IT technologies, many other ideas and suggestions are waiting for their implementation. The preparations and feasibility studies for the next levels of the digital support of further important processes in the various departments have already been concluded or are in the planning stage.

CONTACT

Max Bögl GmbH & Co. KG

Herr Holger Urselmans

Max-Bögl-Str. 1

92369 Sengenthal/Germany

+49 9181 909-11724

GTSdata GmbH & Co. KG

Herr Herbert Fehlauer

Zinngießerstr. 12

31789 Hameln/Germany

+49 5151 107380