Strakon 2022 – reinforcing the proven way

According to DICAD, the 2022 version of its Strakon structural, reinforcement and precast design software is setting new standards in BIM, structural, architectural and bridge design.

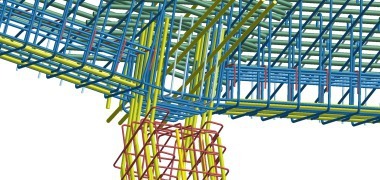

After three years of redevelopment from scratch, the third-generation reinforcement software has reached a very high level of performance. It incorporates not only the expertise of the developers, gained over several decades, but also numerous user suggestions and requests. This makes Strakon 2022 a technically advanced and at the same time practice-based solution for digital, flexible BIM reinforcement design. The model-based Cube reinforcement technology permits faster, more intuitive and more direct reinforcement planning, which now also includes round components.

The new “free placing field” function supports faster and formwork-independent planning of rebars and meshes, for example, if the reinforcement cannot be directly linked to the formwork edge. Since the reinforcement of one flex component can be copied to another, but can also be stored in the library as a reinforcement copy for later use, it is now easier to plan similar reinforcement situations. With the so-called “PXML meshes”, Cube reinforcement now also supports machine-compliant planning as well as the numerical control of mesh welding systems.

Easier cooperation using project models

Compared to the conventional drawing model, where the 3D models are stored in drawings, the new project model offers advantages in particular for the cooperative editing of large projects: the entire model is located in the Strakon project area, where it can always be viewed and edited in parallel by all members of the project team. To ensure that everyone involved knows who is permitted to make changes in which area of the project, the project is divided into submodels. Submodels allow model areas to be shown and hidden quickly and control the assignment of user rights.

It is also possible for one editor to make changes in various submodels across different floors. Older planning statuses can be called up at any time via automatic project backups, and project partners without direct access to the project model can also be involved in the planning process. Joint editing of the project, for example, architectural and structural design in a single model but from different locations, is thus made more convenient. In precast construction, shop drawings can be transferred from the drawing model to the project model in order to use them as templates for the next component. In addition, the shop drawing not only permits editing of one’s own flex components but also provides access to other project items without having to switch drawings.

More convenient communication via BCF Manager

Strakon 2022 also supports BCF, the BuildingSmart standard format, which makes communication between project partners more convenient. Within the parameters of joint project planning, the BIM Collaboration Format simplifies the exchange of information, tasks or questions between the project partners. In addition to textual information, a BCF message transmits the location of the relevant object of discussion in the model, including the viewing direction and a screenshot, thus enabling the project partner in question to immediately see what is being discussed. BCF messages can be exchanged with the project partner, for example, via e-mail. Online project communication via the “BCF Manager” from BIMcollab, which has been integrated into Strakon 2022, is more convenient. It permits any identified errors, discrepancies or collisions to be discussed and important information to be exchanged conveniently directly in the Strakon project.

OpenBIM with IFC

As data exchange via IFC is increasingly used for the BIM model exchange or the alignment of specialist models, Strakon also supports OpenBIM processes with a certified, current version 4 IFC interface. The new 2022 version automatically converts walls contained in the IFC file into Cube walls, which can subsequently be edited as standard Cube walls or turned into a double wall. If the IFC file contains sweep objects, for example in the form of columns or beams, these are transferred 1:1 to Strakon. They can be manipulated via handles, or information such as width and height can be used for automatic labeling in the drawing. Negative objects and wall openings are also exported as IFC objects, including all data. This simplifies the design of recesses, slots and openings, for example, in collaboration with the project partners.

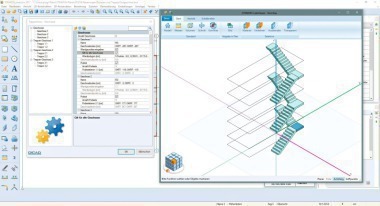

Parametric bridge design for increased flexibility

The functionality of the bridge and tunnel designer in Strakon 2022 has been enhanced to permit automated BIM design of bridges, tunnels and engineering structures. The respective BIM model can be adapted at any time and serves as the basis for creating the drawing with automated curve, longitudinal and cross sections. New features added to Strakon 2022 include horizontal and vertical additional curves, which can be used to conveniently create widenings, haunches or forks in bridges. Longitudinal curve sections can now also be entered more conveniently and provide optimum results, for example, when designing substructures: these are not displayed as a development but, in line with bridge construction, orthogonally in longitudinal section and with the true lengths.

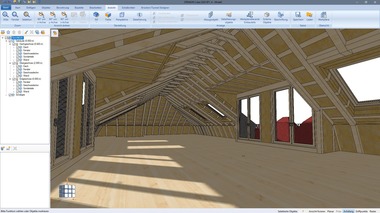

3D steel construction integrated

A powerful 3D CAD steel construction system has been integrated into Strakon 2022 with the Stahlbau 3D “Virtual Steel” add-on module. It permits the convenient design of steel structures such as roofs, ceilings, balconies, platforms or standard staircases made of steel – inclusive of all connections, shop drawings and detailed drawings. The add-on module has been integrated into Strakon 2022 to allow working in a single model. Users simply switch back and forth between solid construction and steel construction functions. The overall model can also be jointly used in both solid construction and steel construction drawings.

Integral design of semi-precast parts

In cooperation with its subsidiary company, BauBit, Dicad is developing a new, integrated design solution for semi-precast parts based on the Cube technology. Strakon 2022 supports the design of double walls and floor slabs – from architectural design via structural design to production. In Strakon, the semi-precast parts combine Strakon’s advanced software architecture with the efficient design methods of BauBit. Coordination errors in the project can be avoided as the semi-precast parts can be optionally displayed or hidden in an overall model. Editors can fully focus on their specific product group, whilst project managers keep an eye on all of the product groups. This permits efficient and economical planning and production of semi-precast parts.

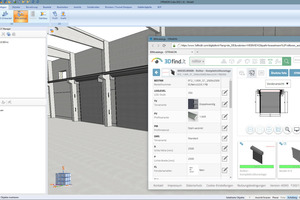

BIM library integrated

Users who do not wish to create specific objects with Strakon, or do not find what they are looking for among the large number of 3D embedded parts in Strakon format provided by various manufacturers such as Ancotech, Halfen-Leviat, Hilti, Pfeifer, Philipp, Primo, Schöck or Simpson, can use online libraries. BIMcatalogs, for example, contains numerous objects and specific products of different manufacturers, such as embedded parts, doors and gates, windows, and many more. This online database has been integrated into Strakon 2022, allowing users to access it directly from Strakon. When the suitable part has been found, it can be created with the desired parameters and incorporated directly in Strakon as an embedded part or flex part at the click of a mouse.

Automation at the precast plant

Strakon 2022 continues to drive automation at the precast plant, for example with the feeding of mesh welding systems or the enhancement of the formwork construction module for controlling formwork milling machines. These new features are included in the 2022 version of the formwork module. On the one hand, it is now easier to design bent formwork boards, which can then be transferred as a development to a CNC milling machine or as a formwork board drawing. Screw holes and drill holes or connectors such as Clamex/Lamello can now also be included in the design in an automated process, as can nailing flanges for fastening chamfer strips. If the formwork boards specified in the design are longer than the supply length of the base plates for the CNC milling machine, they can be divided and then transferred to the CNC milling machine with a groove or rabbet connection at the face of the formwork board.