The new DAfStb Guideline on UHPC

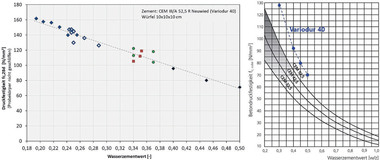

On a worldwide scale, ultra-high-performance concrete (UHPC) has been the single most important development of the past few decades in the field of concrete technology and application. This type of concrete is considerably more durable than normal or high-performance concrete. Its high compressive strength of over 150 MPa enables significantly more slender, weight-saving structures that provide the same load-bearing capacity and greater durability in comparison to similar structures made from normal concrete at a roughly identical price level. For instance, UHPC makes it possible to produce pipes with greater chemical resistance whilst in many cases eliminating the need for additional protective measures, which results in higher value for money. Furthermore, the environmental impact of structures can be reduced by up to 40 %.

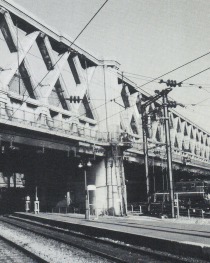

Its excellent performance characteristics increasingly make UHPC the material of choice for the construction of new as well as the refurbishment and upgrade of existing buildings or structures worldwide whilst often utilizing the knowledge and experience initially gained in Germany. Precast elements are used for most projects. In Malaysia, for example, more than 100 bridges have already been built from precast UHPC components, consistently underrunning the cost of conventional concrete structures.

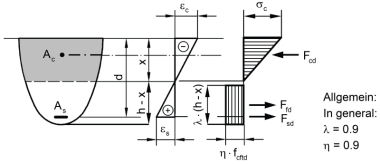

In Germany, this future-proof technology continues to be used only to a very limited extent despite the wide range of benefits that UHPC brings, perhaps because there are no verified engineering codes and standards yet. The German Committee for Structural Concrete (DAfStb) is currently drafting the Guideline on “Ultra-High-Performance Concrete”, which complements DIN EN 206 and DIN 1045, Parts 2 and 3, as well as DIN EN 1992-1-1 (EC 2) to cover all aspects related to UHPC, including input materials, composition of appropriate mixes, concrete production, and design and detailing of structures for which UHPC is specified. According to the current work status, the guideline will also refer to quality control at precast and ready-mixed concrete plants as well as to actual construction. It should contribute to reaping the significant rewards that UHPC brings in terms of modern, long-lasting, environmentally friendly, and cost-effective buildings and structures in Germany.