Wash off concrete wall panels in a closed loop water circuit

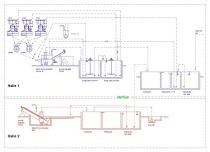

Valcke Prefab Beton NV in Vlamertinge in Belgium produces large amounts of washed out wall panels every day. During this process, large amounts of wash water mixed with cement and particles are created. Together with our client, Ecofrog GmbH has developed a fully automatic continuous process, which allows treating the incoming 40 m³/h of wash water in such way that they can be reused in a closed loop for the panel wash system. This process includes the elimination of particles from the water as well as reduction of the alkaline content.

Process description

The wash water created during the wash off the wall panels (up to 40m³/h) is collected in a channel leading the wash water to a waste green concrete reclaimer RE_X 26. In this reclaimer, the particles larger than 0,250 mm are separated from the water cement mixture by principle of flotation. All particles larger than 0,250 mm are discharged via an ascending dewatering vibration chute onto a conveyor belt transferring the washed out material to a stock pile. The remaining grey water charged with fines, cement and color pigments are collected in a pump sump equipped with an agitator operating in intervals to avoid caking. Via a submersible pump this grey water is pumped to a large attenuation tank.

Another submersible pump is responsible for flushing the channel with this grey water. In this holding tank (Volume 80 m³) a first dosing of carbon dioxide takes place. Via a pH probe, the pH value is measured and the correct amount of carbon dioxide is added to the grey water. The chemical reaction carbon dioxide with the grey water creates carbonate, which stays suspended in the water. The installed agitator prevents the fines from settling and caking and provides good mixing of the carbon dioxide in the grey water. Via a powerful submersible pump this water fines mixture is pumped to a water treatment silo Aquare_X. On its way to the silo, specially selected flocculants are added to the water. These flocculants guarantee a rapid settling of the fine particles and an excellent clarification of the formally grey water. The flocked particles settle in the cone of the silo. A scraper mounted in the cone helps to discharge the fines and reduces caking on the walls of the cone Clarified water mounts upwards towards the roof of the silo where it overflows towards a holding tank.

Clean process water is reused for concrete production

As soon as enough particles have been accumulated as sludge in the cone this sludge is extracted from the silo by a peristaltic pump, which feeds the sludge into a fully automatic hydraulic filter press unit RE_Xpress. Due to the pressure created by the peristaltic pump the sludge is pressed through the filter cloth. The sludge is retained by the filter cloth and filter cakes are created. As soon as the filter cakes are ready, the filter press opens and the filter cakes drop into a collecting hopper. The clarified water that has been collected in the holding tank is again treated with carbon dioxide to achieve a pH value of 7. A submersible pump is then responsible for pumping this water to the general clean water attenuation tank from which the factory is supplied with clean process water, which is reused for the pane wash process and for concrete production.