New residue concrete recycling system for Lindermayr

Lindermayr GmbH & Co. KG is a company based in Friedberg-Derching. Founded in 1961, the Lindermayr company is now operating in the fields of ready-mixed concrete, building construction and civil engineering and is running a precast concrete company and gravel quarry. For recycling and treating the occurring residual concretes and accumulating washing water accordingly, the company decided to invest in a Bibko residual concrete recycling system as well as a Bibko chamber filter press.

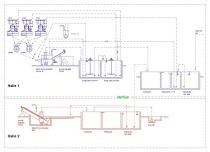

In order to process the arising residual quantities rapidly, they opted for the ComTec30 system. The machine is equipped with a pump discharge conveyor, taking up the residual material from the concrete pump directly by means of a hopper set at ground level. The hopper of the pump discharge conveyor was provided with an accessible heavy-duty grating for minimizing the accident risk. A helical conveyor system carries the residual material to the washing-out unit installed at ground level. The pump discharge conveyor is running in an elastic trough bottom, thus allowing also conveying the existing water apart from the residual concrete. The actual washing-out unit is equipped with a 3.2m wide feeding hopper and two washing gantries.

Recycling capacity of 30 m³/h

The separate pump discharge conveyor allows for simultaneous washing of truck mixer and concrete pump which have separate washing stations. Here, a helical discharge conveyor with a length of 2.5 m provides for perfect discharge of the washed-out material.

The system is completely furnished with recycling water treatment so that the residual concrete is directly fed into the machine after filling the truck mixer with recycling water via the charging hopper and via the pump discharge conveyor, respectively, in case of concrete pumps. Solid materials > 0.2mm are washed out in the washing trough accordingly and are discharged. The water together with the smaller fine particles runs through the water drain into an agitator basin, equipped with an agitator. In this way, the fine particles in the residual water are kept in motion by cyclic stirring, avoiding the sedimentation of residual concrete.

The recycling water containing the fine particles is pumped with increased pressure into the chamber filter press using a compressed air diaphragm pump and thus it is purified. The fine particle contained in the water are pressed by the corresponding filter plates, which are covered with special filter cloth, to form a solid filter cake that is afterwards ejected by automated vibration of the press.

The chamber filter press supplied is equipped with 16 filter chambers.

CONTACT

Bibko Umwelt- und Reinigungstechnik GmbH

Geschäftsbereich Platz

Steinbeisstr. 1+2

71717 Beilstein/Germany

+49 7062 9264-0