Binders for cast-stone blocks –

which binder for which applications?

Dyckerhoff Weiss has given building and design with concrete ever-new impulses for more than 90 years. With the sort differentiation “Strong types from Dyckerhoff Weiss”, it was already possible in the past to offer cement solutions for optimally serving various applications. Cement types with greater fineness and therefore increased performance (52.5) were made available.

These cements make it possible to realize cross-sections of reduced slenderness – or to optimize cement proportions by using various fillers.

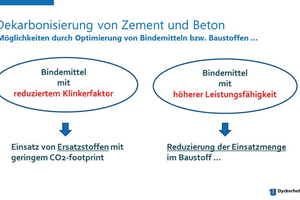

The present challenge is to transfer white cements into a CO2-efficient future. Pozzolans, for example, are possible substitutes for clinker. In addition, natural pozzolans such as those of volcanic origin, and artificial pozzolans such as calcinated clays, can in this context be interesting input materials for the manufacture of white cements.

The combination with unburnt limestone can also allow additional interesting binder alternatives for various applications.

Apart from clinker-reduced binders, however, new opportunities are opening for binders with higher performance than conventional cements. One special characteristic of such high-performance binders is that the amounts of binder and/or of construction materials can be reduced by realizing, for example, smaller cross-sections − thereby saving resources at the same time.Furthermore, the use of high-performance binders can as a rule enable significant increase in durability and, consequently, significantly longer concrete service life of concrete.