Concrete recycling for reducing the CO2 footprint in the construction industry

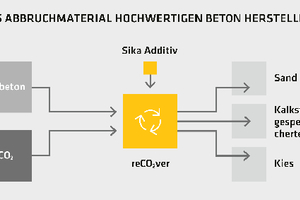

Sika, a leading manufacturer of specialty chemicals, has developed a new recycling process for old concrete in which the recycled material is made available in higher quality than is the case with conventional recycling processes. By this process, the old concrete is broken down into the components gravel, sand and limestone powder in a simple and efficient process: one in which, in addition, approx. 15 kg of CO2 per ton of the crushed demolition concrete material can be bound. The brand name of this innovation is reCO2ver and significantly contributes to reducing the ecological footprint of the construction industry.

In 2020, according to the German Federal Office of the Environment, 76.9 million tons of demolition rubble were generated in Germany, 63 million tons of which were recycled. However, the greater part of this material is used in road construction (38.7 million tons) and earthworks (17.7 million tons). Only 15 million tons are used as aggregate for production of asphalt and concrete. The granulate from demolition concrete could be put to good use in the production of new concrete. For this purpose, demolition concrete is broken down, cleansed of foreign matter and sorted according to grain size.

Utilization of recycling concrete reduces the mining of gravel and heavy goods traffic by shorter transport distances. Its use has been permitted for a number of years in the relevant standards, but it is rarely considered in invitations to tender. The situation is different in the USA, Belgium, the Netherlands and Switzerland, where already up to 15 % of the total amount of concrete is processed as recycling concrete.

Concrete producers may substitute up to 45 % of the aggregate by recycling material that satisfies the standards DIN EN 12620, DIN 4226-101 and DIN 4226-102 – and 25 % where the environmental impact is greater. The limitation depends on the exposure class. The situation is different, for example, in Switzerland, where 100 % of recycled construction material may be added to the mix.

Pilot plant set up near Zurich

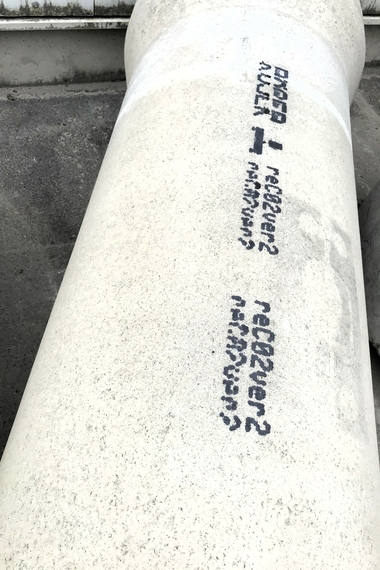

The sector has high hopes that it will also be possible to store CO2 in the processing of concrete rubble. For this purpose, Sika has set up a pilot plant in Weiach near Zurich. The plant consists of four modules, of the size of an overseas container, as well as an upstream conveyor system and a downstream sieve module. Precrushed material is delivered in BigBags and transported via a conveyor belt system into the core of the plant: the ball mill. There, the crushed old concrete is further broken down with the aid of metal balls and the gravity principle. The process rubs off hardened cement paste that adheres to sand and aggregates. Subsequently, the material is automatically discharged from the mill. During this process it is possible to adjust the input material to the properties of the output material by adapting various parameters such as the filling height of the material, the material throughput and the specific rub-off conditions and in this way influence the properties of the output material.

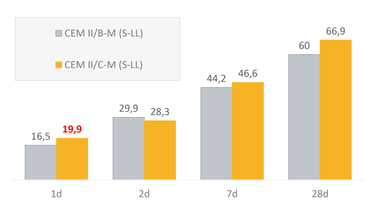

Additional conveyor belts then transport the treated material into the sieving plant, which divides the material according to the desired particle size. In addition, the hardened cement paste powder generated during the process is extracted and fed in prepared containers into an airtight system. The recycling material derived has a considerably lower content of adhering hardened cement paste powder and can therefore be used for a wide range of applications. Experiments performed by Sika have furthermore shown that a certain amount of the hardened cement paste powder can be used in concrete production, which in this way enables use of less cement and reduces the CO2 footprint of new products.

New reCO2ver technology

The plant, in addition to the high quality of the recycling material, offers the possibility of performing CO2 sequestration. For this purpose, pure CO2 is added to the hardened cement paste powder and recarbonated in this environment: i.e., it absorbs CO2 and stores it. The tests so far performed on a laboratory scale have shown that absorption of 50-60 kg of CO2 per ton of hardened cement paste posder is possible.

Dr. Carsten Rieger, Corporate Market Development Manager of the Concrete Business Unit (Concrete Admixtures) at Sika AG in Zurich explains: “Our reCO2ver technology enables us to achieve a complete circular economy with concrete.” The new process completely reutilizes concrete waste – which, for example, no longer end up in landfills. In earlier tests based on alternative processes for recycling old concrete, the rate of reutilization was comparatively less and only 30% of the recycled raw materials could be used as substitute in structural concrete. The innovation from Sika enables production of high-performance concrete together with high binding of CO2.

CONTACT

Sika Deutschland GmbH

Kornwestheimer Str. 103-107

70439 Stuttgart/Germany

+49 711 8009-0