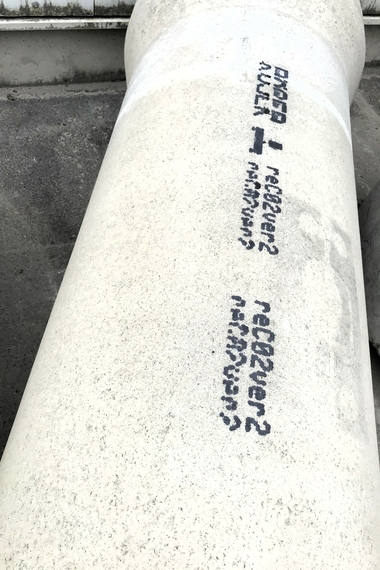

Interview: The new reCO2ver recycling process

As described in the preceding article, the company Sika has developed a new recycling process for old concrete that can produce recycled material of higher quality than is obtained by conventional recycling processes. This innovation with the brand name reCO2ver makes a significant contribution to reducing the ecological footprint of the construction industry.

Dr. Carsten Rieger, Corporate Market Development Manager of the business unit Concrete (Concrete Admixtures) at Sika AG in Zurich, gave the BFT editorial office an interview.

BFT International: Dr. Rieger, what is the difference between reCO2ver and other concrete recycling processes?

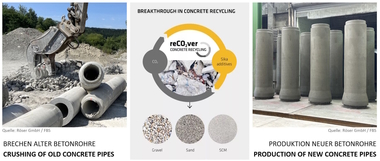

Dr. C. Rieger: With conventional concrete recycling, the old concrete is reduced to pieces of various sizes, with diameters down to 32 millimeters. These fragments are used as aggregate for new concrete. This method has many disadvantages because these fragments have a greater surface area and greater porosity than aggregate of primary rock. With the reCO2ver process, the rock fragments are divided into their various components: i.e., rocks and the hardened cement paste powder. The hardened cement paste powder, in addition, reacts with CO2 (carbonation) and binds it to the powder.

BFT International: What is Sika doing, in addition to the pilot plant, to promote the building of larger and commercially more sustainable plants?

Dr. C. Rieger: The tests initially performed in the pilot plant have confirmed the efficiency of the process. As early as during the pilot phase, we conducted tests with materials from customers. These tests have also shown that the reCO2ver process results in considerable advantages in recycling. The findings gained in the pilot phase were included in a design for a possible large-scale plant.

BFT International: Will emerging countries also be able to afford these plants, or will their use be the prerogative of industrial nations?

Dr. C. Rieger: These plants will be of interest wherever a market for recycling concrete exists and where infrastructure for sorting and cutting concrete waste is available. Currently, this is primarily the case in industrial countries. However, as soon as incentives for concrete recycling have been created, and when a market develops in this direction, reCO2ver plants will become economically viable elsewhere as well. The investment into a plant must be compared with the added value that it offers. This lies in the value of the reclaimed material and, indirectly, as a result of the CO2 bound by the material.

BFT International: What commercial interest does Sika have in disseminating this reCO2ver technology?

Dr. C. Rieger: Sika wants to reduce CO2 emissions in the construction industry – and this we are doing. Moreover, we are the owner of this process patent and therefore entitled to license the process. More opportunities will result from the use of additives for enhancing the quality of the reclaimed materials and from the sale of CO2 certificates.

BFT International: What is the special feature of the Sika additives used in connection with the reCO2ver process?

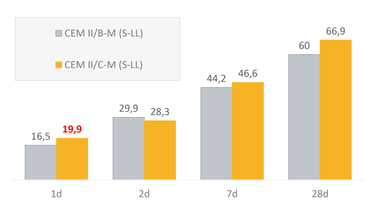

Dr. C. Rieger: Sika has developed several admixtures that, apart from the reCO2ver process, will help our customers to manufacture recycling concrete more efficiently and to reduce the CO2 footprint of concrete. Among these are additives that influence the processability of recycling concrete as well as improve the quality of the powder reclaimed from the reCO2ver process. This will optimize its performance as substitute for cement.

BFT International: What are the findings gained from the pilot phase?

Dr. C. Rieger: Last year we successfully concluded the pilot phase. This means that we clearly demonstrated that the reCO2ver process functions with concrete rubble on a large scale and under real conditions. We significantly reduced the water demand of the recycling material (-60%) and the separated powder employed with approx. 15kg CO2 per ton rubble material. Beyond that, some insights could be gained on how to design a more efficient process. These were already incorporated into a design of a large-scale plant that we can now make available to our customers.

BFT International: What resonance do you expect for concrete recycling and the use of recycling concrete? Have you already received feedback from the industry?

Dr. C. Rieger: The companies that are already active in concrete recycling are very much interested in the reCO2ver technology because it would greatly facilitate concrete recycling and make it commercially more profitable and more sustainable. We can see that concrete recycling will be introduced wherever there is political commitment for it and the legal framework has been created.

BFT International: Do you believe that political incentives or regulations will be required for promoting concrete recycling?

Dr. C. Rieger: Regulations for reducing CO2 emissions already exist, and the reCO2ver technology is one of the few processes that sequesters – in other words, binds – CO2. This is in the interest of all participants. Regulations that would specifically promote concrete recycling would, in our view, make sense.

BFT International: How would you quantify the market potential for reCO2ver?

Dr. C. Rieger: In Europe alone around 300 million tons of concrete rubble are generated annually. Worldwide, we assume a volume of approx. 600 million tons annually. We estimate the global market that Sika can reach to be around five percent of this amount. That would, for the time being, result in 30 million tons of concrete rubble annually.

BFT International: Dr. Rieger, many thanks for the conversation und much success furthermore!

Interview: Dipl.-Ing. (FH) Silvio Schade, Editor-in-Chief BFT International

CONTACT

Sika Deutschland GmbH

Kornwestheimer Str. 103-107

70439 Stuttgart/Germany

+49 711 8009-0