Sika solutions for sustainable building with concrete

To achieve the necessary CO2 reduction in construction, the processes and the materials used in this industry must become more sustainable, among others in construction chemistry. Towards that end, Sika Deutschland GmbH makes an important contribution in various sectors – as illustrated in the following article.

To achieve the necessary CO2 reduction in the construction industry, its processes and the materials used must become more sustainable. All parties participating in construction are challenged to modify their processes and to apply new methods as well as alternative construction materials. Various approaches exist on how the construction-chemicals industry, for example, can implement this. Sika Deutschland GmbH provides an important contribution here in various sectors. The following examines innovations including closed-circle economy by reCO2ver technology for improving resource efficiency, possibilities for reducing the clinker content in cement production as well as the use of CO2-reduced concretes.

The primary industries with their high share of process-related emissions offer a large savings potential for avoiding greenhouse gas emission. Around 30 % of the total emissions are generated in the steel, 20 % in the chemical and nearly 10 % in the cement industries. Here, innovative, climate-friendly technologies and, in particular, rethinking of production and utilization of construction materials of all kinds is needed. This is possible over a wide range of quite different areas – beginning with cement production and proceeding to placing concrete at the construction site.

1 CO2-reduction in cement production

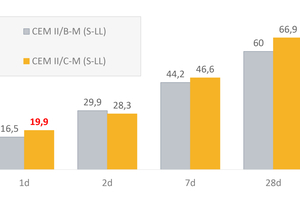

The major share of CO2 emission in cement production is process-related. To reduce emission, the clinker content for Portland cement, which is the mostly widely used type, must be significantly lowered. Alternative cements without Portland cement clinker are being developed, but still require five to ten years until they can be used and produced in large quantities. The focus is accordingly on minimizing the share of clinker in cement. A significant reduction of clinker content, however, also changes the properties of the cement. As a rule, the early strength of clinker-reduced cement, for example, is less than that of cement with higher clinker content. For the processability of the concrete at the construction site, this means that construction elements made with less early-strength concrete would have to remain longer in the form at the construction site. Use of a strength-increasing admixture of the SikaGrind series can compensate for this already during cement production (Fig. 1).

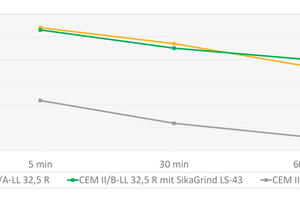

Limestone is the most cost-effective addition to concrete which the cement industry has available in sufficient quantity. The benefit therefore seems obvious, i.e. to manufacture cement with limestone content as high as possible. But a high limestone content also makes the cements stickier. That, too, can be icompensated by adding suitable cement admixtures so that grinding in greater shares of limestone admixture allows maintaining the same workability properties (Fig. 2).

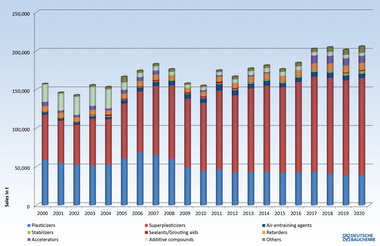

In addition, the use of grinding aids in cement production can make grinding more effective. It increases the performance and, at the same time, reduces specific power consumption. The optimization also lowers CO2 emission. The German Association of Manufacturers of Chemical Construction Products, for example, has calculated that, in a ball mill with consumption of 4,000 kW, 95 tons of cement can be ground in one hour without grinding aids, resulting in energy consumption of 42.1 kWh. With grinding aids, the ball mill achieves 116 tons and consequently consumes only 34.5 kWh/t – for energy savings of 22 % (source: Deutsche Bauchemie).

2 CO2-reduced concretes

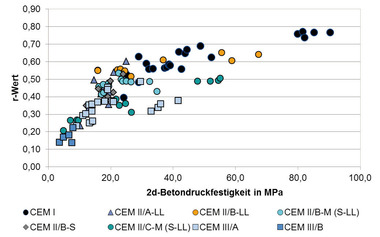

Use of CO2-reduced cements (see section 1, above) is the easiest way for manufacture of CO2-reduced concretes. In precast construction, CEM II/A is often used instead of CEM I; for ready-mixed concrete, this is CEM II/C-M or CEM III/A instead of CEM II/B.

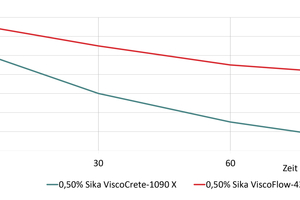

With regard to the admixtures for concrete used for this cement change, the question of whether the existing superplasticizers can still be used is particularly interesting – and whether batching will change. In the most favorable case, no changes will be necessary to achieve the usual workability – neither to the product nor to the batching. In some cases, however, it has been observed that the amount of superplastizer used must be significantly increased to achieve the customary workability.

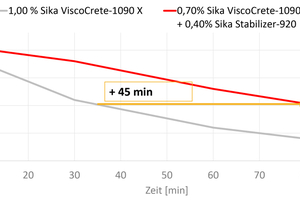

In cases where this, too, is not sufficient, the problem is usually a loss of consistency in the course of time. Here, a superplasticizer adapted to the new cement must be developed. The solution may, in most cases, be a superplasticizer with a slump keeper or a slump-keeper superplasticizer.

The combination of products consisting of superplasticizer with slump keeper contains, in addition to the slump-keeper polymer, an even stronger liquefying component and can therefore be used as sole superplasticizer. An example of this is shown in Fig. 3 for a CEM II/B-M.

Slump-keeper superplasticizers consisting of only a slump-keeper polymer are commonly processed in the plant in addition to the concrete liquefier or superplasticizer typically used. This two-component approach enables optimal control of consistency maintenance.

In order to compensate for the disadvantages in early strength in cements with a significantly lower clinker content, use of hardening accelerators may be advisable, which, however, is expedient only in certain cases. The reason for this is that maximum efficiency of commercially available hardening accelerators lies within a time window of approximately six to ten hours. For this reason, use of hardening accelerators such as SikaRapid C-100 is required only when early strength is necessary within this time window: e.g., in precast plants or with interior tunnel forms. An increase in early strength at later points of time can be achieved by reducing the water-cement ratio. An increase in superplasticizer dosage thereby compensates for disadvantages in workability.

3 Innovative closed-circle economy with the reCO2ver technology from Sika

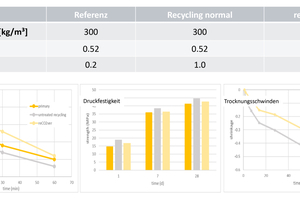

For recycling concrete, the old concrete is broken up in crushing plants and subsequently screened and separated into size fractions. Grain sizes smaller than 2 mm, according to current standards, may be reused for concrete, and chips larger than 2 mm may be used only in limited quantities. Chips consist both of rock grain and of grains with adhering hardened cement paste. Owing to the cement paste content, chips have a higher water requirement. As a result of the crushing process, moreover, chip grains have a more unfavorable shape than round grains. Accordingly, they as a rule need more water: i.e., they must be presoaked or supplemented with stronger superplasticizers to ensure workability.

With the new reCO2ver technology from Sika, the concrete is, in fact, divided into individual parts, which results in clean granular material of primary quality: i.e., sand and powder with certain pozzolanic properties. It can therefore contribute to the development of strength and can be used either for cement production or as an addition to concrete. Accordingly, 100% utilization of the originally used concrete is possible, and clean granular material is completely used as such (Fig. 4). Furthermore, CO2 is added in the process and the powder is carbonized: i.e., it absorbs CO2.

The reCO2ver technology from Sika includes both the process of size reduction and carbonation in one compact plant. It simplifies not only concrete recycling but also renders the process more economically profitable and sustainable (Fig. 5).

Initial experiments in a Swiss pilot plant have so far been successful. At the same time, admixtures for enhancing the quality of the recovered powder have been developed and their performance as cement substitute further optimized. This technology, for the first time, makes a closed-circle economy possible for concrete in producing high-performance concretes from old concrete.

4 More efficient utilization of scarce resources

Especially in the sector of ready-mixed concrete, it has become apparent that greater utilization of increasingly difficult sands are being used for concrete production. Some years ago, these sands were not even considered for concrete production. Although, in Germany, large deposits of high-quality sands do exist, they are not available because these areas were assigned for other uses – or permissions for their quarrying is difficult to obtain. The utilization of difficult sands has an adverse effect on properties of concrete such as workability. Phenomena of various kinds result, including insufficient slump despite high doses of superplasticizers, more pronounced undesirable loss of flowability of the concrete and lack of production of air voids. In order to utilize sand deposits more cost-effectively and sustainably, Sika developed the C.O.D.E. concept, a procedure for resource optimization in concrete production (Fig. 6).

Clay minerals contained in sand, with their various properties and consequently resulting effects, may be the reason for this phenomenon. Sika has developed new analyses and testing methods for limiting these problems and for finding solutions. An example for this is the PCE absorption analysis by means of which it can determine whether a clay mineral has a high water requirement or whether it absorbs superplasticizers. These are two entirely different phenomena that must be treated in totally different ways. The newly developed test methods are, firstly, important for precisely narrowing down on specific problems and, secondly, for finding appropriate solutions based on the knowledge gained on the processes – e.g., the Sika Stabilizer-900 series. These solutions are employed for concretes by utilizing the following:

Sands with absorptive constituents such as swellable clays,

Sands containing many fine particles or

Sands causing pronounced loss of flowability.

The great advantage is that a change in the dosage of the Sika superplasticizers used previously is not required (Fig. 7).

5 Improving the CO2 footprint by using less steel

Substitution of steel by synthetic fiber is a topic that has been discussed in the expert community for some time. One advantage is that construction progress is significantly faster when using synthetic fiber instead of steel reinforcement. In addition, polymer fibers are non-corrosive and the previously necessary concrete cover is no longer required. Slimmer construction elements are possible, making production in the precast industry still more cost-efficient. At the same time, the danger of damage during erection and transport is drastically reduced, since the polymer fibers are distributed up to the surface and corners and edges are more stable.

Considering, for example, the reinforcement of industrial floors, approximately 75 % of CO2 can be saved by using SikaFiber Force-50. Extrapolated to the approximately 8 million m² of concrete floors installed yearly in Germany, this results in potential savings of around 63,000 tons of CO2 per year (source: Deutsche Bauchemie). Furthermore, the microfibers from Sika are manufactured in Germany and therefore require only short transport distances.

6 Digitization in the construction industry is more necessary than ever

Digitization in the construction industry makes an important contribution to sustainability and must continue to be vigorously encouraged. Especially 3D concrete printing is frequently mentioned in this context. It offers numerous solutions for avoiding waste and offers a means of responding to the increasing shortage of skilled personnel.

In particular, additive manufacturing processes – i.e., superposing extruded concrete layers – enable the following:

An increase in productivity in the concrete industry,

Overcoming the shortage of skilled personnel in construction,

Cost-effective batches (this already applies to manufacture of one-offs),

Continuous digital workflow,

Reduction of construction waste and

Far-reaching freedom of design.

At this time, 3D printing is primarily still based on dry concrete, which is mixed with water and printed. For this purpose, various ready-to-use micro-concretes are offered under the name Sikacrete 3D for a wide range of applications, ranging from concrete furniture to printed houses. They can be easily and uniformly processed with all commercially available printers. In addition, a 3K high-end solution is available for the most challenging requirements (Figs. 9 and 10).

7 Concluding remarks

Especially by its development and further progress, construction chemistry provides a major contribution to sustainability and to reduction of CO2 in the construction industry. All current concepts function only with the appropriate admixtures for cement and concrete. Previously, the objective was technical optimization. Today, it is sustainability and enhancement of the CO2 footprint.

CONTACT

Sika Deutschland GmbH

Kornwestheimer Str. 103-107

70439 Stuttgart/Germany

+49 711 8009-0