Digital Monitoring, Documenting, and Controlling of Processes: AAC Plants on the road to Digital Transformation

The Production Reporting System developed by Masa combines the information worlds of the operator and management levels and makes products traceable.

Which solutions do we have to meet growing requirements on AAC production plants? Do we still dare to control production processes with expertise only? Or do we need systems instead that connect the information worlds of the operating and the management levels? Systems that better harmonise production and processes with market requirements and company goals?

The Masa Production Reporting System can be an answer to these questions. It supports the processing and management of the flow of information and forms the functional level between the plant control system and the customer’s ERP system.

It is the task of the AAC manufacturer to integrate incoming orders into the operative production process in that way that a detailed resource planning, product tracing and documentation as well as requirements regarding production and quality assurance are considered constantly. In the long run, paper-based documentation, pure operator knowledge, separate spreadsheet analyses or isolated applications are not sufficient to support operators and management appropriately.

A comprehensive, dynamic system, however, monitors, documents and controls the complete manufacturing process based on information, from the raw material to the finished product. It provides data for decision-makers that help to produce more and more efficiently in the end. Considering all this, Masa developed another milestone of the complex Masa plant control system: The Masa Production Reporting System.

Advantages of a digital modul

The digital module “Masa Production Reporting System” supports the coordination of workflows, tasks and resources of the company. Productivity, efficiency, and cooperation within the production plant can be optimised thus. This means, among other points:

The system uses real-time data. The user can trace and analyse the status of resources such as machines and material. He can schedule orders and arrange them according to priorities. Thus, the available resources can be used and coordinated precisely. In the end, the productivity can be enhanced, and cycle and reaction times can be reduced.

The system administrates the complete production process from the order release to the finished product. Deviations in quality can be traced, specifically analysed, and corrected. This improves the quality management.

The degree of automation of the complete plant is increased. Various plant components adapt themselves automatically in case of a product change. Paper-based processes can be reduced as far as possible. The likeliness of human errors in the production process decreases.

Administrative efforts are reduced. The data collected during operation on processes, materials and workflows do not have to be recorded and transmitted manually. They are available for decision-makers centrally, edited and immediately accessible.

Decision-makers can use the prepared data for performance analyses. The comparison of results and targets enables the detection of strengths and weaknesses of the complete process. This allows sections and processes to be organized more efficiently.

The system documents the complete production process, from first to last step. It interconnects the finished products with the corresponding production data. These data from the complete history of a product provide production evidence. With this, manufacturers can draw conclusions to possible production mistakes.

To make it short: Main tasks of the system

The Masa Production Reporting System fulfils three main tasks along the lines of the general definition of Manufacturing Execution Systems (MES) [1]: The production data acquisition (PDA), the locking and the traceability.

Production Data Acquisition (PDA)

The system provides the data referring to the respective station anytime, that is, independent from production. It determines various operating figures on-line and evaluates them, e. g.:

Waiting times

Processing times

Capacity utilisation

Availability

Locking of the station

Depending on the product to be manufactured, the system locks a processing station. This is to make sure that all station parameters are adjusted correctly before the station is passed and production resp. treatment begins. Main operating figures are:

Automation of product change

Examination of the set-up parameters

In case of a product change, the system in the Masa AAC manufacturing plant switches many processing stations automatically. Should this not be possible, additional information is displayed. This leads the operator through the manual setup of the station.

Traceability

The traceability marks the end of the processing of a product. In these data, the process parameters and the processed material are recorded. The following data may be interesting for assessment and evaluation:

Production evidence

Detection of production errors

Quality intensification

Limitation in case of recall

One system for two target groups

The Masa Production Reporting System comprises two presentation levels (Frontend). These are tailored for the target groups “Plant Operators” and “Decision Makers”. They enable access to all product-relevant data and conditions from mixing to packaging.

An SQL database (Backend) structures and stores the data. The interconnection of two hard disks and the inversion of the data (RAID 1) guarantee for a complete redundancy. Thus, the Masa system ensures a high degree of fail-safety.

Target Group “Plant Operators”: The presentation level for the Doer in the factory.

The plant operator and the production plant communicate via a process visualisation system. The user interface for visualisation and operation is designed in that way that it shows the well-known Masa structure.

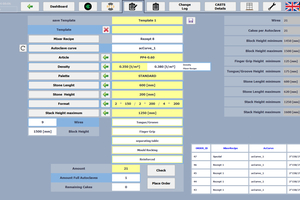

The DashBoard displays the most relevant, already processed data. It is individually customisable. The plant operator gets a quick survey of the most important present plant data and conditions. By means of icons, the operator can navigate to the individual levels of the Masa Production Reporting System.

Order Edit: Creating a production order

Here, the operator creates a production order that is automatically identified with an ORDER ID. The mix recipe itself with specific information regarding the raw materials has previously been created and stored in the mixer control system. The ORDER ID comprises all parameters relevant for production.

The system actively supports the operator to minimize input errors: For each product, various individual boundary conditions are defined. As part of a plausibility check, the system automatically prevents the release of the order and highlights those fields graphically in which the input values have to be corrected. The system also provides the opportunity to individually extend these limit values.

Order: Administration of the current orders

The operator adds the created orders to a waiting line (Queue). The system processes this list sequentially. However, if the priorities need to be changed, the operator can flexibly adjust the sequence before starting the order.

Cast Details: Detailed information on each cast

Here, the operator can retrieve comprehensive information for each individual cast. This comprises, among others, information regarding the oiling of the moulds and side plates, start and duration of the casting process, fermentation, hardening time inside the autoclave, cycle time at the individual plant sections and working stations and information regarding delays.

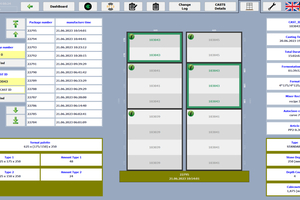

Packages: Tracing of individual product packages

The system assigns a unique package number to each package, which is printed onto the package label. This package number allows a retracing to the respective cast (CAST ID). As the package is in fact packed sorted regarding size and type, but the blocks can originate from different casts, the system documents the individual composition on each transport pallet.

With the package number and the CAST ID, the system thus offers widespread possibilities to analyse errors, the consideration and evaluation of the time intervals between casting and start of autoclaving for example.

Change Log: Logging of changes

The system conducts a Change Log in chronological order. This automatically records all important changes to preset values by the operator. With this, the Change Log offers a clear and transparent survey of the development, and changes made. This can help the operator to correct errors by means of a stepwise, documented adaption of parameters as well as to locate errors.

Tagging the transport media: Distinct identification

The prerequisite for the traceability of products is the complete recording of the product, from its origin throughout the complete production process to the point when it reaches the end customer.

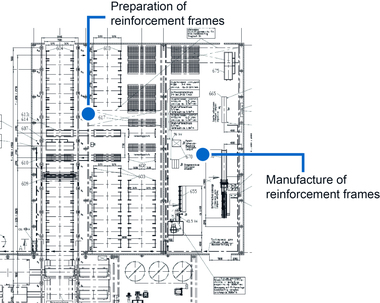

In the AAC production process, however, not the individual element or an individual block is tagged. Masa clearly identifies the transport media used during the manufacturing process so that the production is traceable.

Depending on the processing station, Masa uses RFID chips, binary coded sign plates or QR code labels. As soon as the material and production data have been “married” to the tagged transport medium, the Masa Production Reporting System takes over: It controls the production order, carries out the handover to the individual processing stations and supplies retrospect information down to the origin of production.

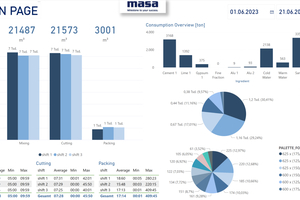

Target Group “Decision Makers”: The presentation level for the Management.

The second presentation level of the Masa Production Reporting System is not designed for the day-to-day routine in the factory. It provides interactive visualisations and business analysis functions for the management. It runs with the help of the business analysis service Microsoft Power BI. Based on the SQL database, this presentation level is subdivided into a Main Page and various detail pages (Sub Pages).

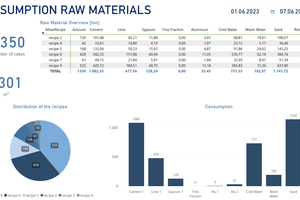

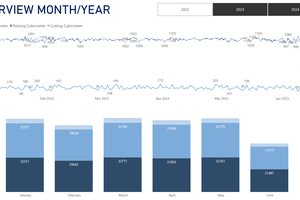

The system enables the evaluation of individually adjustable periods of time or production shifts that can be reviewed together or separately. The data can be exported as CSV file. Via an interface, the data exchange to the customer’s ERP system is possible. The Main Page displays important key figures, prepared in terms of content and graphics. It summarises all relevant figures and information. It is easy to orientate oneself: The Main Page uses the bar, column, and pie charts common in reporting.

The Sub Pages visualise different categories, such as the output in relation to the mixing, cutting, and packaging processes or the raw material consumption per recipe within a defined period.

The evaluation options and visualisations of the Masa Production Reporting System actively support the management in planning, control, and monitoring tasks. Process and product optimisations are always based on a systematic approach, targeted analyses, and specific root cause research. With the help of detailed shift, product or raw material evaluations, the operator of the AAC production plant can draw profound conclusions about optimisation measures and thus make his plant more efficient.

Conclusion

Standstill is a step backwards. Masa is working on the further development of the Production Reporting System. Currently, the development team in Porta Westfalica is programming a tool that records and visualises the energy input and consumption in the individual plant sections. This will be presented at bauma 2025 in Munich. Furthermore, the development team is working on a maintenance tool to extend the Masa Production Reporting System, for example.