Flexural design of ultra-high-performance

fiber-reinforced concrete girders

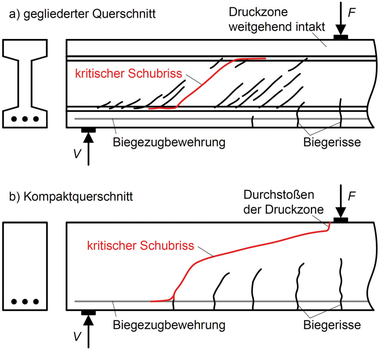

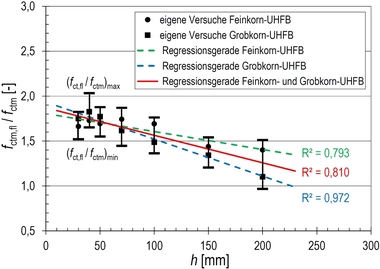

In [1], an approach for determining the moment resistance of ultra-high-performance concrete (UHPC) girders with mixed reinforcement is presented. This approach considers the contribution of the steel fibers by means of a stress block. The ultimate strain Ɛcfu of the stress block is not a fixed value but refers to a critical crack width. Reaching the critical crack width marks the maximum contribution of the fibers in the flexural crack and the beginning of the so-called strain localization, meaning that the subsequent increase in deformation is concentrated on a single crack – the failure section. For cross-sections with mixed reinforcement, strain localization is another possible failure mode in addition to the well-known modes of flexural tensile failure and flexural compression failure. A so-called structural characteristic length is used to convert the crack width into strain. The structural characteristic length takes account of the section depth and other parameters affecting crack formation.

The design approach is validated in [2] by means of a test database. This database considers different cross-sectional shapes and reinforcement configurations, namely members that are prestressed, exclusively steel fiber-reinforced, and exclusively rebar-reinforced, as well as members with mixed reinforcement. When being evaluated using mean values of the material parameters, the model fits well for both the universe of the tests and individual model parameters. The ratio between the experimentally determined moment resistance and the theoretical moment resistance Mexp/Mcal amounts to an average of 1.09 for the 177 beams with compact cross-section, 1.01 for the 31 beams with I-section, and 0.94 for the 20 beams with T-section. The coefficient of variation is 0.19, 0.13, and 0.11 for the three types of cross-section. An acceptable level of safety is obtained by limiting the characteristic value of the post-cracking tensile strength to 0.6 times the mean value.

![Fig. 1: Design approach for UHPC girders with mixed reinforcement [1]](https://www.bft-international.com/imgs/2/0/9/0/5/9/4/tok_f9088c0fd441fe982268953ca9d73b1c/w300_h200_x600_y295_12_7_Leutbecher_Abb_neu_red-a651cd0943938fcb.jpeg)