Ground-breaking use of Precast Concrete Anchors new Motor Museum

In a very special application of precast concrete in South Africa, 12 U-shaped precast concrete elements, manufactured by Concrete Manufacturers Association (CMA) member, Cape Concrete, have been used as the primary anchor material for the construction of a motor museum at Lourensford Wine Estate in Somerset West.

In a very special application of precast concrete in South Africa, 12 U-shaped precast concrete elements, manufactured by Concrete Manufacturers Association member, Cape Concrete, have been used as the primary anchor material for the construction of a motor museum at Lourensford Wine Estate in Somerset West.

Limited by town planning to a maximum 900m² footprint, architect Anton Heyn designed the building to resemble a barn and to accommodate as many cars as possible, 42 in all, as well as motorbikes and other memorabilia. “To a large extent the exhibition space determined the shape of the precast concrete elements ,” said Anton Heyn. “In order to optimise our limited space allowance, we angled the two lateral faces of each column at 20º to create an additional 20% of exhibition space. This not only allowed 10 cars to be parked in two opposing fanned crescents in each display bay, but improved viewing angles as well.” A 3m wide central section, which runs the full length of the barn, forms the viewing area and another two cars can be displayed in the reception area situated in the middle of the building.

Self-compacting concrete was used

The roofing also comprised four 15m x 2.6m in-situ slabs which were cast between the Zincalume roof sections and were supported at each end by the precast elements. The slabs were tapered from 350mm to 250mm to provide a slope for rainwater which drains into the hollow sections of the U-shaped precast units.

In addition, eight 15m x 2m (height) in-situ beams were cast on either side of the four concrete roof slabs to support four wooden truss assemblies for the Zincalume roofing and its ceilings. The precast units are founded in 120mm (depth) x 200mm (width) U-shaped channels which were cast into the footings.

“We had to increase the depth of the footings to ensure we didn’t compromise their structural integrity,” said structural engineer, Gawie Combrinck, managing director of GFC-Holdings. “The original design had a 50mm cover above the reinforcing steel but it was not enough to accommodate the founding channel. So we increased the cover to 150mm to give us the required 120mm channel depth. Once a precast unit was lowered into a groove it was shimmed level and sealed with a flowable non-shrink grout.

“When I first arrived on site I thought to myself this is beautiful concrete. I realised then that it heralded a spectacular concrete display, because with tolerances of less than 4mm on each, the precast elements were as perfect as you can get them. There is not a single crack on any of the precast units thanks to some heavy reinforcing.

Cape Concrete director, Walter Botes, commented that because an off-shutter finish was required on all sides, the precast structures were cast vertically. “This entailed pumping self-compacting concrete from the bottom of the mould, a process which eradicated air bubbles without the need for external vibration and gave a much smoother finish. The precast structures were cast with rebar extensions at the top to tie into the cast in-situ roof beams. The four corner precast units were cast with an additional concrete wing to which the timber barn doors have been attached. These units are all identical, except that two were cast with door openings for staff access. A single mould was used for casting all 12 units but the mould required some slight modification for casting the four corner units.”

Precast concrete is very flexible and malleable

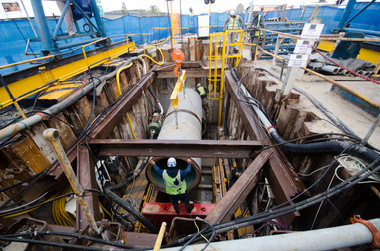

“Transporting the units to site required careful planning. Weighing 13 tonnes apiece, they were lowered onto their side and delivered two at a time. Using lifting anchors cast into the top of the units, they were tilted into the upright position before installation. We used a four-legged chain running over two rollers, belt slings and a spreader beam to lower the columns into position,” said Botes.

“This project is quite unique,” added Anton Heyn, “and was completed in what was a fixed budget. Precast concrete is a very flexible and malleable building material and I can’t think of any better material which we could have used, especially as we needed to opt for shapes which offered better space utilisation.

“I’m very happy with the excellent finishes achieved by Cape Concrete. As an architect one couldn’t have expected better than this. It’s what we visualized and it’s turned out perfectly,” concluded Anton Heyn.

The motor museum follows the contours of the site and the flooring in each bay section is stepped down 200mm. The floor has a very smooth finish which was protected during construction with plastic sheeting and a layer of sand.

As direct sunlight fades vehicle paint over time, the museum’s lighting is generated artificially and naturally; diffused natural light is supplied by four corner windows in each display bay and by windows above the reception area. And an air pressure system has been installed to keep the museum as dust-free as possible.

The museum is linked by a path to the Lourensford market area where, in a second phase of the project, additional cars will be displayed in redesigned shipping containers.

The landscaped area surrounding the museum comprises an orderly combination of exposed aggregate paving, cobble paving, gravel-covered paths, grass, potted plants and flower beds.

Concrete Manufacturers Association member, C.E.L. Paving Products, supplied 500m² of its Brownstone course exposed aggregate paver which was used to pave the vehicle entrance areas at either end of the building and a section flanking the museum’s main entrance. C.E.L. also supplied its bond paver which was used as the paving’s header course.

Anton Heyn said he specified C.E.L.’s Brownstone paver as one of the main landscaping elements because it is an attractive and durable non-slip product which complements the site’s other landscaping elements.

“The paver is embedded with natural stone which adds a natural look and feel to the museum’s landscaping ‘language’. We could have specified an in-situ paving installation but given that the site was built with several services which require maintenance or add-ons from time-to-time, paving blocks proved to be the more practical solution; they can easily be lifted and replaced without damaging or marring the paved surface.”

Anton Heyn

GFC-Holdings

(Gawie Combrinck)

Piet Bentum

Build A Way Construction

Cape Concrete

Hannes Pretorius

Gideon Roos

Koos Jordaan, Tinus Potgieter