Sika solutions for sustainable building with concrete

The BetonTage combine a high-quality technical program with an informative exhibition for the professional and corporate trade public. More than 2,000 visitors from around 20 nations meet from 14 to 16 May 2024 in the Congress Centrum in Ulm to compare notes and to network at the largest specialist congress for the concrete industry in Europe. At stand 79, Sika Deutschland GmbH presents its products and solutions on all aspects of sustainable building with concrete.

The 68th BetonTage take place under the motto “Shaping Transformation.” Peter Löschnig, Marketing Field Manager for Concrete Admixtures at Sika says, “We offer one of the most comprehensive and most innovative product ranges for high-quality concrete production. For the interested trade public we present our solutions for sustainable building with concrete, including two innovations: the Sand App and the filling and compaction aid SikaPaver-620.”

Quick analysis of aggregate with the Sika Sand App

The Sika Sand App makes the analysis of aggregate more efficient and faster than ever before and therefore represents one of the most important tools for building experts. An analysis of particle size distribution and shape parameters is possible directly from the mobile device. In addition, the app provides information on roundness and aspect ratio, and it uses all theoretically available sieves. This not only makes projects more efficient, but also contributes to sustainable and cost-effective building practice. The Sand App from Sika can be installed and set up on any mobile device (both on iOS and Android platforms.)

New filling and compaction aid – SikaPaver-620

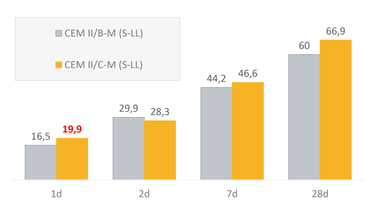

With its SikaPaver-620, Sika presents a new product for more sustainable and cost-efficient production of concrete products. The new filling and compaction aid, based on the time-tested product SikaPaver HC-218, enables application of more sustainable CEM II/C-M cements for the production of concrete products, which reduces CO2 emissions of the no-slump concrete by 30 % in comparison to the previously common CEM II/A. CEM II/C-M cements made with SikaPaver-620 can be processed more effectively at constant water content. Improved flowability leads to more uniform filling of the form, up to 20 % faster compaction and therefore higher quality.

Innovative circular economy with reCO2ver technology from Sika

Application of reCO2ver technology from Sika breaks down concrete into its individual constituents, which results in clean aggregates. This means sand and gravel of primary quality as well as powder with specific pozzolanic properties. This can contribute to strength development and enables use either in cement production or as admixture for concrete. In addition, it is possible to add CO2 in the process for carbonating the powder. The process of size reduction and carbonation is included in one compact plant. It not only simplifies concrete recycling, but also makes it economically more profitable and more sustainable.

More efficient utilization of scarce resources

Especially in the ready-made concrete sector it has become apparent that the sand types used in concrete production are increasingly difficult to handle and process. These are sand types that a few years ago would not have been considered for concrete production. To enable cost-efficient and sustainable use of sand resources, Sika has developed the C.O.D.E. – a concept for resource optimization in concrete production.

Improving the CO2 footprint by using less steel

Specialists in our field have long since discussed substitution of steel by synthetic fibers. For reinforcement of industrial floors, SikaFiber Force-50 enables reduction of approx. 75 % of CO2 per cubic meter of concrete. Extrapolated for the approx. 8 million m² of concrete floors installed annually in Germany, this would result in a reduction potential of around 63,000 tons of CO2 annually [source: German Construction Chemistry]. In addition, the micro-fibers are manufactured in Germany, resulting in short transport routes.

Digitization in the construction industry more necessary than ever

Digitization in the construction industry makes an important contribution to sustainability and must continue to be pushed. In this context, especially 3D concrete printing is frequently mentioned and offers many advantages for waste avoidance and in view of the increasing shortage of skilled personnel.

Currently, 3D printing is to the greater part based on dry concretes which are mixed with water for printing. For this technology, various ready-to-use micro-concretes are offered under the name of Sikacrete 3D for a broad spectrum of applications – ranging from concrete furniture to house printing. These concretes can be simply and uniformly processed on all standard printers. In addition, a 3K high-end solution is available to meet the most stringent demands.

CONTACT

Sika Deutschland GmbH

Kornwestheimer Str. 103-107

70439 Stuttgart/Germany

+49 711 8009-0