Magnet technology of the future: New impetus for

precast plants thanks to research and development

Modern precast concrete plants manufacture both solid concrete walls and sandwich walls, while attaching great importance to highest efficiency. The production processes become more and more demanding, because they are engineered for optimum efficiency. In this effort, precast concrete plants opt for solutions that are not only resource-conserving, but also allow for a seamless integration into the entire workflow. To comply with this increasing requirements, the Magdeburg-based B.T. innovation GmbH is constantly developing their own magnet technology and shuttering systems.

Innovative product range – Versatile solutions for each individual case

The innovative product range is quite diversified and offers the right solution for each individual case. Along with a growing degree of automation of the precast concrete plants, the demand for robot-guided shuttering systems increases too. Therefore, BT innovation provides precisely manufactured solid shuttering systems with integrated attachment for robot gripper according to customer‘s request respectively.

The solid shuttering system can be ordered in individual lengths, heights and with specially shaped profiled sheet. Adhesive forces of up to 22,000 N per magnet ensure firm hold on the formwork table. But, BT innovation also offers efficient solutions for precast concrete plants with fewer automation. For manual operation, all solid shuttering elements can also be equipped with the innovative MagButterfly magnet system. The system simplifies detaching the shuttering elements from the formwork table. Owing to a specially developed guiding of the magnets, which are reminiscent to the wings of a butterfly in their arrangement, the force for deactivating the magnets can be reduced considerably.

Easy handling – flexible removal and alignment

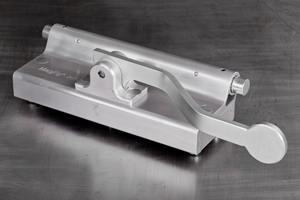

Apart from the MagButterfly, BT innovation‘s portfolio includes even more magnets. Another modern shuttering magnet of BT innovation is the MagFly AP. It is part of the BT shuttering system and is quick and easy to position and fix. With its impressive adhesive force to mass ratio as well as the foot and spring system that allows the magnet to slide effortlessly over the formwork table, it is most helpful when it comes to realizing works in a time- and labor-saving manner.

The magnet is activated as soon as firm pressure is exerted on the top of the same. Then the force of the magnet adheres to the formwork table. Handling proves to be quite simple: With the integrated lever, the magnet can be released and realigned easily and quickly. Moreover, no additional tools or adapters are require for inserting the MagFly AP. The lightweight housing allows for ergonomic working without effort.

Perfect harmony with the BT shuttering system

The BT shuttering system provides an optimum solution for precast concrete plants. The combination of MagFly AP and perfectly matching MultiForm formwork elements, like the MultiForm type 1, MultiForm type 2, MultiForm (MFE) corner connection and window and door openings, enables versatile applications. No matter, whether concrete wall, window or door openings, the MagFly AP and the BT shuttering system are in perfect harmony and simplify the production of various precast concrete elements. Even sealing between formwork table and chamfer strip is eliminated, as the MagFly AP presses the shuttering system firmly to the formwork table.

MagFly universal magnet – Versatile range of applications

Another highlight among the BT magnet line is the MagFly universal magnet. With various adhesive forces, dimensions and designs, it offers a wide variety of applications. Adapters and accessories can easily be attached to the MagFly universal magnet, allowing the implementation of individual applications in an optimum way.

Research for the future – Efficient magnet technology

BT innovation has successfully met the challenge to improve the magnet technology continuously for the production of precast concrete elements. With MagButterfly, MagFly AP and other innovative magnet systems, the company once again demonstrates its ability to coordinate effective technologies perfectly, while significantly accelerating the production of precast concrete elements. As a pioneer in magnet technology, BT innovation sets standards in the concrete industry and supports precast concrete plants in organizing their processes more efficiently and in a more resource-conserving manner. Constant research and development have made B.T. innovation GmbH an expert in magnet technology for the concrete industry, offering customized solutions that meet the individual needs of the industry. With a motivated team of experts and a strong focus on quality and customer satisfaction, B.T. innovation GmbH characterizes the precast concrete industry and helps to sustainably shaping the future of the construction sector simultaneously.

CONTACT

B.T. innovation GmbH

Sudenburger Wuhne 60

39116 Magdeburg/Germany

+49 391 73520