Market potential for precast bridges – resource-saving employment of UHPFRC precast segments

The majority of concrete bridges in use in Germany are in extremely poor condition and must be replaced in the near future. The construction of new build bridges, however, entails immense CO2 emissions that primarily originate from the concrete and from the steel used in concrete. Accordingly, there exists an enormous need for research into ecologically sustainable as well as cost-efficient construction methods in building concrete bridges. In addition, traffic restrictions (detours, congestions, etc.) and the resulting CO2 emissions, that result in the construction of new bridges, must be reduced to a minimum. Utilization of precast segments of ultra-high-performance fiber-reinforced concrete (UHPFRC) is a highly promising approach to construction that is fast, efficient and resource-optimized.

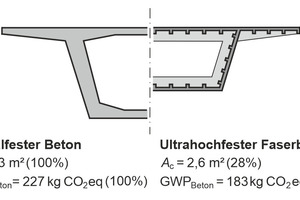

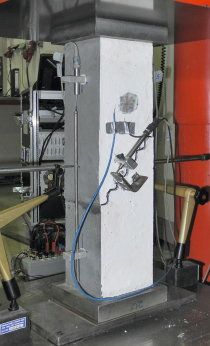

To study this construction method in greater depth, several segmented box girder bridges were investigated, with work based on a monolithic box girder bridge of normal-strength concrete, and by varying the compressive concrete strength (normal, high and ultra-high-performance concrete) using finite element computations. It was found that UHPFRC segments, due to their high material strength, can be designed with great slenderness compared to segments made of normal and high-strength concrete (see Fig. 1). A subsequently performed life-cycle analysis for phases A1 to A3 showed that, in addition to the use of resources, the Global Warming Potential (GWP) can also be markedly reduced. Additional considerable CO2 savings are possible as a result of shorter construction time with segmental construction methods at the site and, as a consequence, with prevention of traffic restrictions.

In summary, it can be seen that UHPFRC precast segments in bridge construction can lead to especially resource-saving and sustainable construction that – in view of the great extent of re-placement construction now necessary – could have an ex-

tremely high market po-

tential for the precast concrete industry.