Ultra-High Performance Concrete (UHPFRC): Practical experiences of executed projects

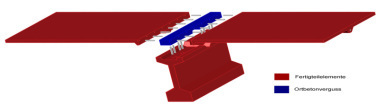

Implenia executed its first projects in Germany in 2023 based on Swiss SIA 2052 standard. To date, the repair of bus lanes or the production of precast concrete components as prototypes for maintaining our railway infrastructure, for example, have been carried out based on approvals on a case-to-case basis.

The Ultra-High-Performance Concrete consists of a purely mineral-based concrete matrix characterized by high compressive strengths of up to 200 N/mm², high bending tensile strengths of over 30 N/mm², increased impact and shock resistance and improved cracking behavior (inhibition of crack formation and crack expansion) compared to ordinary concrete, and a steel-fiber reinforcement.

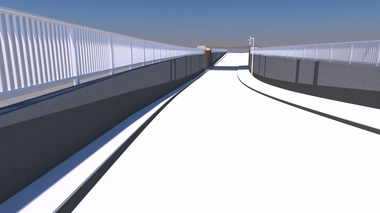

These properties allow UHFPRC to be used, for example, for traffic surfaces, industrial floors, bridge decks, reinforcement measures or in precast concrete construction. In the projects carried out, it also acted as a waterproofing and protective layer and, not only in these cases, has represented a resource-saving and time-efficient alternative to conventional reinforced concrete. In Munich, two bus stop lanes were built with the aim of achieving significantly extended durability and reduced wear due to the exceptionally high strength and density of the UHPFRC. Additional projects are about to be implemented nationwide, and a relevant guideline from the DAfStb is expected. Material producers see the German market as promising and have therefore initiated first approvals for the construction products.

As a major European construction and real estate service provider

Implenia has many years of experience with this future oriented construction material, which has been successfully transferred to the German market and is one of the subjects of this year’s presentation.

It will also cover recent developments of the UHPFRC in terms of durability and performance to actively contribute to resource conservation.