Mesh welding lines for the production of small and medium size mesh

Eurobend GmbH offers the most comprehensive line of automatic machines covering every precast application: From the entry level welding lines producing simple reinforcing elements and AAC blocks reinforcements, to complete plants producing precast mesh, rebar cages, mesh/rebar spacers, trusses, girders and rebar forms (in 2-D & 3-D shapes).

The PLR Compact Series

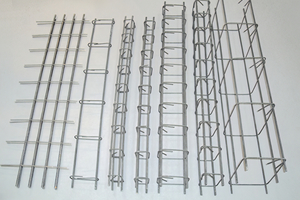

Among the Eurobend range of welding machines for the production of standard construction mesh, engineering and precast mesh, the PLR Compact Series focuses on the production of small to medium mesh sizes, which are used primarily in concrete reinforcing cages and other similar products for the precast industries.

The PLR Compact Series of mesh welding lines offer servo-motor driven operation, and ensure 0simple machine layout, reliable and cost-effective production of mesh sheets from coils, for line and cross wires. The machines are designed to offer ultimate flexibility and unlimited processing capabilities on the production of a wide range of concrete reinforcing elements.

All types of mesh used in concrete blocks, pre-cast elements and other prefabricated concrete products, (cages, channels, etc.) can be produced. The mesh can be further processed in independent working mesh bending stations for the production of mesh cages. The PLR Compact Series, set new standards in the production of small to medium size welded mesh, as it combines a unique compact design –as the name denotes- with increased automation and production flexibility.

Furthermore, the fully automatic operation of the PLR Compact Series ensures high quality while minimal operator involvement is required. The PLR Compact Series can process up to 12mm coiled wire.

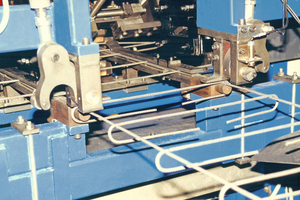

Independent and individually adjustable welding heads

Welding is achieved through a number of independent and individually adjustable welding heads covering different product widths and line wire spacing. Repositioning of the welding heads can be achieved in shortest time, due to our unique quick release mechanisms, which allow accurate and easy changeovers. The PLR Compact Series, offers also programmable line wire feeding, allowing automatically adjustable variable cross wire spacing within the same mesh sheet without any manual interventions. Line wires are fed directly from coils through a compact straightening and multi-roller feeding unit, which offers exceptionally accuracies.

For the feeding of cross wires, there are two methods available, one which features feeding directly from coil and one from pre-cut bars, through an automatic rack type feeder.

User friendly software

All PLR Compact Series are equipped with an ergonomic operator interface with user friendly software which offers remote access via Internet for troubleshooting and routine maintenance. Programming is easy to understand and follow and does not require any special programming skills.

Operator is only required to supervise the production process and remove the automatically produced and stacked mesh sheets.

PLR Compact models are available with:

Offset carrier for curved mesh sheets,

In-line cross wire overhang bending heads and wire trimming stations,

Cross wire welding above and below the line wires for compact stacking – no mesh turning station required,

Automatic mesh stacking systems and palletizing systems,

Automatic labeling systems,

Mesh transportation and bundling systems.