Quality control and more in the Spotlight at bauma

When bauma opens its doors in Munich this April, visitors to the Masa booth in Hall B1.347 can expect a great mix of new and proven products. While the basic technology for producing blocks and pavers hasn‘t been revolutionised since the last bauma, a closer look at Masa‘s booth reveals significant advancements, particularly in quality assurance of concrete products.

Masa will showcase its new product for non-contact inspection and measurement of concrete products in Munich. This inline system detects various product defects, measures product height across the entire production board, and inspects the boards themselves. The streamlined quality control module is fully integrated into the Masa plant control system, allowing operators to use the familiar interface.

Tradeshow premiere of a learning system

The Masa system for optical quality control is set for its Munich debut. Over the past few months, Masa has optimised the prototype in live operations, fine-tuning settings, visualisations, and design at a pilot customer. The prototype has successfully passed test runs in a real production environment, with the integrated AI-supported evaluation software learning daily. Ahead of bauma, you can already catch a glimpse of the system.

Measure inline

On the wet side, the system performs non-contact measurements on freshly produced concrete products directly behind the block/paver machine. The wet side conveyor continues to transport the production board with the products without delaying production or stopping for measurements. For producers, this means quality control without any loss of time.

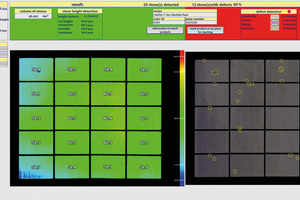

Detect product defects at an early stage

The system detects a wide range of product defects, distinguishing between surface defects and impurities. It visualises and classifies deviations from the standard in the Masa plant control system and marks the detected products. The system identifies:

Surface defects from a size of approx. 1 mm²

Lifted areas on the surface with a height difference of about 0.5 mm

Fine cracks from a width of approx. 0.5 mm and

Cement balls.

Thanks to early fault detection, the system actively helps the machine operator optimise production. As the operator receives immediate feedback about product irregularities right after the demoulding process, they can quickly adjust machine settings, recipes, or raw materials, reducing rejects. Depending on the type and quantity of defects, it may be advisable to remove the entire production board with fresh products before curing, using the optional Masa tilting device. This ensures that the curing area is filled with flawless products, preventing subsequent complaints. If only a few products are faulty, they can be sorted out on the dry side.

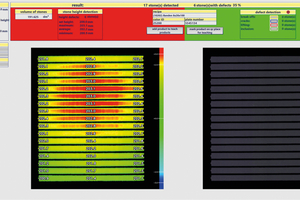

Determine product height

The system scans the concrete products as they pass under the device without making contact and measures the product heights across the entire production board. The visualisation interface displays the block height in colour, based on the specified tolerances.

Inspect production board

The condition of the production boards, which serve as the transport medium for concrete products, directly affects the quality of freshly manufactured concrete items. Any damage, unevenness, or deflection in the production boards negatively impacts the products, leading to increased costs due to rejects. This is where the quality control system plays a crucial role. It inspects empty production boards for potential quality defects and identifies these within defined tolerance limits in the Masa plant control system.

The technology in the device

To integrate the device, which contains all the measurement technology, into the production plant as space-efficiently as possible, Masa developed the slimmest possible design. This allows the quality control system to be installed in new plants and retrofitted in many existing ones.

During bauma 2025, Masa cordially invites interested visitors to their booth to get a firsthand look at the quality control system and its capabilities for precise and continuous product inspection. Developers and sales staff will be available to answer questions about the technology „in and on the device,“ such as surface scanners, optical cameras, or encoders. They will also discuss installation options, practical applications, and the benefits of quality control.

bauma 2025 – The Masa booth offers even more

In addition to the new system for optical quality control, many other current Masa milestones will be spotlighted for visitors in Munich in Hall B1.347, presented in both analogue and digital forms.

The online world of the Masa Service Cloud has been expanded and will be showcased at the booth, along with a special feature for digital transformation in AAC plants. The Production Reporting System, developed by Masa experts for AAC production, will also make its tradeshow debut. This tool connects the information worlds of plant operators and management, making products traceable down to their production data on the day of production.

A prominent exhibit from the „Concrete block production“ area will offer insights into Masa machine technology and a broad perspective. An installation from the AAC production section will provide a deeper view. Masa will also create ample space for sand-lime brick specialists. bauma 2025.

The Masa team looks forward to seeing many visitors.