Segment production for Vienna‘s U2 is running at full speed

Wiener Linien is expanding the metro line system with the U2xU5 major project. For the construction of the new U2 line, a tunnel boring machine is used that allows for removing the entire excavated material via a central shaft at the square ‚Matzleinsdorfer Platz‘. The concrete rings (‚tubbings‘) required for the continuous driving process are manufactured at Maba Fertigteilindustrie GmbH located in Wöllersdorf near the city of Wiener Neustadt. More than 19,000 individual segments (with six segments forming a concrete ring) will be installed in the line tubes between the stations.

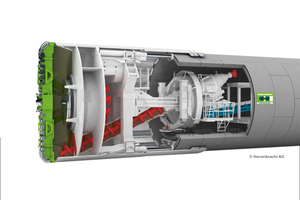

The Debohra tunnel boring machine of the supplier Herrenknecht, that is used for the expansion of the Vienna U2 line in southern direction, being more than 120 m long and weighting 1,300 t, is already hard at work. The tunnel segments (so-called ‚tubbings‘) that are used in both directions of the line tubes between the stations of Matzleinsdorfer Platz, Reinprechtsdorfer Straße, Pilgramgasse, Neubaugasse and Rathaus (City Hall) on the U2 construction lots U2/18-21 with an overall lengths of approx. 4 km have already been prefabricated at Maba Fertigteilindustrie GmbH since the end of 2023. Adequate stock had to be made available already for driving the tunnel tubes so as to deliver the 10 to 12 concrete rings, which are now going to be installed per day, to the temporary storage at the construction site more or less just in time.

Resource-efficient and

environmentally-friendly tunnel construction method

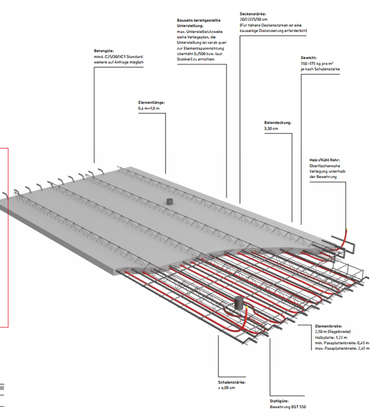

The tunnel boring machine (TBM) ensures tunnel construction in a highly sustainable manner: with a cutting wheel, having an excavation diameter of roughly 7 m, the TBM is continuously working through the underground. After a boring distance of 1.5 m, a concrete ring is installed each, thus forming the tunnel tube step by step. Each concrete ring consists of six individual segments – the so-called tubbing segments – which had been prefabricated under optimum conditions at Maba previously and are installed precisely fitting by the TBM. As soon as a concrete ring is installed completely, the tunnel boring machine can push itself away from the same, thus continuing boring. The six segments forming a complete ring have slightly different geometries which are manufactured at the highest accuracy to the tenth of a millimeter, while already undergoing continuous inspection by employees of the Wiener Linien company at the factory during the entire production phase.

Using 35cm-thick tunnel rings, just the exact amount of concrete and reinforcement is used that is required to meet the specifications.

Climate project with

exemplary character

Undoubtedly, the U2 x U5 public transport expansion is one of the most important projects of infrastructure and climate protection for the City of Vienna. The construction project itself is planned and implemented as efficient, environmentally-friendly and local residents-friendly as possible, according to the statement provided by U2 project manager, Helmut Schweiger (DI-FH) of the department of infrastructure development and realization / metro new construction south at Wiener Linien: „By using a tunnel boring machine, we avoid approx. 20,000 truck transports in total for the removal of the excavation material in the center of the city alone. This reduces, of course, the burden on the citizens of Vienna significantly, because at a construction project of this scale, the burden on the neighboring residents and business people is correspondingly high, in fact.“

Premiere for MABA

Fertigteilindustrie at the headquarters

For the U2 construction lots between the squares of Matzleinsdorfer Platz and Augustinplatz realized by a joint venture comprising Porr and Strabag, for the first time, the segments are manufactured in stationary production in the main production halls of Maba Fertigteilindustrie GmbH based in Wöllersdorf – and not, as was the case at previous major tunnel projects of Maba, like the Wienerwald Tunnel, Koralm Tunnel or Boßler Tunnel, in an especially erected field factory at the tunnel portal.

„The favorable position south of Vienna, the short transport routes and the confidence in an enterprise that has already been contributing a considerable part to Vienna‘s infrastructure with its expertise and its huge product portfolio for a century now, contributed to the fact that we were awarded a contract by ARGE U2 17-21 finally,“ states the authorized representative Stefan Kizlink.

„After the many stunning segment projects of our group of companies from the Koralm up to Stuttgart, we are particularly pleased that we can provide our expertise so to say on our doorstep,“ says Michael Wardian, General Manager of Kirchdorfer Group, who is delighted too.

Segments: Squaring the

circle in tunnel construction

The first segment was manufactured in the Maba factory based in Wöllerdorf on November 23, 2023. Until the start-of-operation date, the storage was continuously filled up with about 36 segments per day. More than 19,000 individual segments were manufactured for the U2 x U5 public transport project.

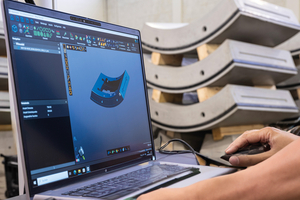

The precast concrete elements are manufactured with the tightest tolerances which are otherwise only achieved in mechanical engineering – a circumstance requiring highly specific know-how. After demolding, the precise geometry is measured and controlled by laser-based Theodolites.

By the way, employees of the Wiener Linien company check the high quality requirements several times per week during the segment production on site directly. This ensures that, later on, the passengers will be transported through an impeccable tunnel structure.

CONTACT

Maba Fertigteilindustrie GmbH

Kirchdorfer Platz 1

2752 Wöllersdorf/Austria

+43 5 7715 400