Stuttgart 21 – Production and installation of heavy-duty paving slabs

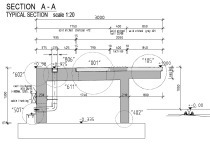

As part of the major project “Stuttgart 21”, the planning, production and installation of paving slabs for pedestrian walkways leading to the railway platforms, were realized with precast concrete. In their geometric shape (rounded), these slabs are matching the chalice-shaped pillars that are already existing on site (Fig. 1), and they are particularly characterized by high requirements on the dimensional accuracy as well as the surface quality. Therefore, the entire planning process was already carried out using a detailed 3D model in order to accurately represent all geometric and technical requirements.

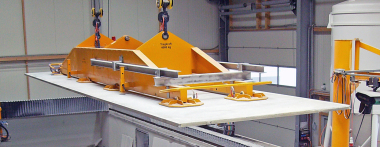

The decision to use precast concrete elements offered significant advantages: They allowed a precise prefabrication under controlled conditions in the factory, facilitating to comply with the strict dimensional tolerances and to ensure the required surface quality.

An extensive development phase in terms of concrete technology, which began well before the start of production in the factory, included a large number of test series to achieve the exposed concrete quality required in SB4 with a light coloring. In this process, the focus was on optimizing a homogeneous concrete mixture that is both seasonally stable and ensures uniform smoothing. The high requirements on the visual quality at the top and bottom side of the slabs were dicisive.

The formwork elements were cut using CNC milling technology to ensure maximum dimensional accuracy. The stainless steel rails used as peripheral edge protection were precisely prefabricated at the factory and exactly integrated in the formwork. For transportation, special stacking frames were designed to allow a commissioned provision of the precast elements according to the installation process and thus ensuring optimized logistics.