Adfil: strongly reinforced for the future

09.07.2019It is no secret that the international concern Low & Bonar wanted to cash in by selling its business unit for Adfil construction fibres in order to invest that money in divisions that, according to the specialist in technical textiles, would yield greater returns. Adfil stands for Anglo Danish Fibres Industry Limited, originally an English-Danish company with headquarters in Hull that produced micro fibres and was acquired by Low & Bonar, which subsequently integrated the production in Belgium.

On our own two feet

Since 2014, Low & Bonar have invested significant sums of money in new macro fibre capacities and a brand new concrete lab in Zele, East Flanders. This has resulted in the production of patented fibres which will ensure Adfil remain at the forefront of producing excellent products. Due to other pressures on the business, the international group decided to embark of selling Adfil resulting in the business coming under new control from 1st July 2019. The new owner is a private investor who has repeatedly invested successfully in companies in the past and who thinks in the long term. The daily management will be in the hands of CEO Tom Winters and COO Ives Swennen, who will both also become directors.

Both men had a hand in the inception of the concrete lab in 2017 and are ‘moving’ along with it, as are all 36 employees and all the real estate and equipment. Tom Winters: “In the Low & Bonar group, everything is produced ‘on a roll’. From a production point of view, we were the odd ones out in any event with our fibres being sent to the customer in bags. We were also very different from other sister companies in the commercial sphere. We were the only ones with a finished product that went directly to the end market. We wanted to offer more service and, as an independent company, we will now be able to make more conscious choices about that.”

The umbilical cord connecting us to Low & Bonar is thus being completely severed. The strong brand name Adfil will also become the name of the new entity, which will remain in Zele. Apart from that, there is also a sales office in the United Kingdom, employing six very experienced technical sales staff.

Alternative to steel

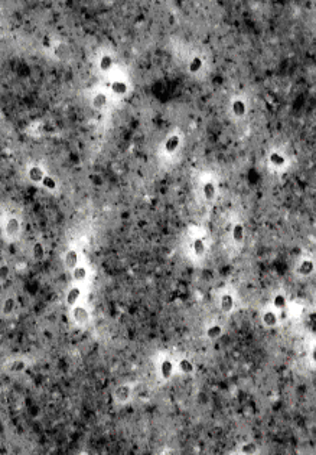

Micro and macro synthetic fibres are increasingly being used to reinforce concrete, as a sustainable alternative and/or supplement for steel reinforcement or steel fibre concrete reinforcement. They are only a few centimetres in size and appear round, flat, spiral-shaped or elongated. You can find them in different colours and they have extraordinarily versatile properties. Ives Swennen: “If you add our fibres, the concrete will dry out more homogeneously, with the result that the appearance of plastic or shrinkage cracks occur less readily. The macro fibres are already dosed in the concrete plant, so the concrete arrives at the construction site already reinforced and can be put in place faster by the contractor. Macro fibres also do not corrode in concrete, as opposed to steel. Everything we do is aimed at improving the longevity of concrete. Adding the correct dosage of fibres even makes steel mesh or fibres superfluous in many applications, such as in concrete internal and external hardstandings, such as pressure layers (screeds) in poured concrete.”

Conquering Benelux

Adfil as a brand has been in existence since 1997 and was renowned for its patented micro fibres. Its business has grown rapidly since these days with the turnover now at over €15 million euros. A good example as to why the business has grown can be seen in Belgium where until a few years ago, the construction sector was not at all tuned in to the enormous technical sophistication and potential of these polymer fibres, but gradually the market seems to be ripening for it. “Yes, in a certain sense we were pioneers in the last ten years, because our solution was new in the market and construction is a relatively conservative sector”, says Tom Winters.

Adfil supplies its fibres globally either directly to concrete plants or via preferred partners. The latter are commercial players who are co-investing in advance and are pushing their brand fully into the market. Most of Adfil’s customers are located outside of Belgium, but gradually the concrete plants in the Benelux are becoming attracted to its fibres. Tom Winters: “Increasing numbers of concrete producers, engineering firms and contractors prefer plastic fibres to conventional steel reinforcement. Those are also the three groups we are hoping to convince.”

Since the middle of last year, Adfil has become very active in Belgium, thanks in part to it having obtained ATG certification. “We needed two years to carry out testing. Those tests were done using the worst-case scenario concrete mixes. The ease of working with and the homogeneity of the concrete were thus proven under the most extreme conditions. What it boils down to is that everything is now certified and everyone is happy with our solutions. Thanks to the certification, Belgian companies often are no longer forced to exclusively use steel for reinforcement. In Belgium, approximately 12 million cubic metres of concrete are poured each year, 95% of which is reinforced using steel mesh, so there is a lot of potential for a better way to carry out reinforcement. Meanwhile, we have been working together with Interbeton, one of the bigger players in Belgium. Our volumes are increasing month by month and every day we are asked to make a new calculation as against conventional reinforcement steel.”

The shortage of suitable workers in the construction sector is also to their advantage. Ives Swennen: “There is a great shortage of steel mesh fixers, which means contractors are lagging behind with their projects. In those circumstances, our solution, without steel, fits the bill. If you do not need steel mesh workers and customers start working with our fibres, they will notice the benefits in their wallets as well. In addition, it is also faster, because with traditional steel reinforcement, half the time is spent on laying the steel reinforcement and half on pouring concrete. With our solutions you save a lot of time, because the fibres are added quickly in the concrete plants.”

New products and applications

Synthetic fibre reinforcement still has a particularly large margin for growth, precisely because so many markets and applications are still unexplored. The dosage (kilograms per cubic metre) is getting lower all the time, from 12 kg to the current 3 kg. Ives Swennen: “This also improves our performance and enables us to use our fibres in more and more applications. We are also continuously developing more fibres that look good visually and with which you obtain a nicer finish with as few fibres as possible on the surface, such as our Durus EasyFinish. This new fibre now accounts for 70% of the sales of our macro fibres. One of the nicest compliments you can get as an R&D department is that your product is automatically accepted by the sales team.

We first started with all-purpose fibres but now we develop fibres for specific fields of application. It may seem trite, but this grey fibre is used more readily than a white one because it is somewhat camouflaged in floor applications and so looks better. The fibre also somewhat resembles steel; even that unwittingly plays a part.”

Adfil tries to innovate in every facet of the fibre: in colour, in bonding the fibre into the concrete and in all the mechanical properties such as impact resistance, tensile strength and stiffness. Ives Swennen: “We want to distinguish ourselves by putting a product on the market that is not based purely on the properties of the fibres, but rather on their actual performance within concrete. To get a good grasp of this principle, we have carried out a great number of external tests, which have resulted in good insight and a strong development model. In this way, we are now able to test the exact composition of concrete using our fibres for customers and thus to know exactly how it will perform.”

“In everything we develop, we prioritise two things. One: it must be easy and pleasant to work with our products, both during mixing and during finishing. Two: the actual performance in concrete must be good”, adds Tom Winters.

Recently, Adfil has launched a new type of fibre for sprayed concrete after a two-year research project in collaboration with Centexbel, the federation of the plastics and textile processing industry. The company also received subsidies from VLAIO, the Flemish Agency for Innovation and Entrepreneurship, for this. “Such innovations are meant to make us fit for the future. In sprayed concrete, there are various products (a combination of fibres and chemicals that is different every time) and they set very quickly. It is a very difficult market in which to gain a foothold as an individual fibre producer; your product has to be very distinctive. Together with a chemical giant, we conducted tests for months on end, both in labs and in tunnels. The performance of this new macro fibre is 20% better than the market benchmark. Tunnels potentially constitute a very large market. Steel mesh is currently attached to tunnel walls, after which concrete is sprayed; we want to ‘attack’ that market. We can also be competitive when compared to steel fibres because we achieve higher energy absorption levels using less product.”

The new owner recently decided to invest in additional sales staff who have both technical and commercial knowledge. “They really are a rare breed”, says Tom Winters. “In order to convince engineering firms or contractors, it is very important that one of our team is able to quickly resolve all technical questions even after implementation.”

In the future, Adfil also wants to reinvest profits back into the company. “Because we are now finally standing on our own two feet, not only will we be able to serve our markets in the right way and grow step by step, but we also want to make our people happier. We are in the process of becoming a small but very flexible player, in which our employees will also combine various roles. That is why we really want to dedicate ourselves to job satisfaction. Because we consider the person behind the employee to be of paramount importance”, they both conclude.

CONTACT

Adfil NV

Industriestraat 39

9240 Zele/Belgium

+44 1482 863777