Innovative and high-precision online density measurement of residual water

Many tons of residual concrete are accumulating every year. Thus, for many years now, the concrete industry has made great effort to pass from mere waste disposal engineering to materials management in closed cycles. This, however, requires new measuring systems and new technologies. Werner & Thiel sensortechnic has taken on this challenge and with the “Olas measuring system” the company has developed a revolutionary online measuring method for the determination of the density of concrete recycling water.

In 2002, the leading company Arnold Automation was taken over by Werne & Thiel sensortechnic. Apart from the continuous further development of the well-proven moisture measuring probes, the new owners have specialized in design and development of an innovative, industrial sensor technology. The development of the Olas measuring system, an online measuring system for the determination of the solids content in concrete recycling water, had started almost ten years ago. Today, a reliably functioning and cost-efficient measuring system is available, which has obtained commercial viability. Olas is named according to its function: “optical light absorption sensor”. It makes use of a highly sophisticated infrared absorption measuring method, which couples the measuring light via optical waveguides into the medium. The worldwide patented development now allows to increase the quality of concrete considerably through automatic and continuous measuring of the density of concrete recycling water. For a closed material cycle in concrete manufacturing, it is required according to EN 1008 that the density in the residual water basin does not exceed the limiting value of 1.07 kg/l. The standard measuring range of the Olas is between 1.000 kg/l and 1.150 kg/l and therefore it well surpasses the required range. Thus, even in case of any temporary exceeding of the limiting value, it is possible to capture the maximum density value in a reliable way and to reduce the same once again by adding fresh water. In the meantime, the results gathered in long-time tests with the first devices of the Olas measuring system produced in series are available. Already in November 2007 such a system used for the surveillance of the density of residual water has been put into operation at Holcim Kies und Beton AG in Diessenhofen (Switzerland). After one year of application in the day-to-day operations the plant manager, Florian Mascherin, draws a first conclusion: “The measuring instrument and the digitally displayed value of the residual water density inform us at any time about the current density in the residual water basin. Thus, we are able to enter the value directly into the production control system. As a result, the quality and in particular the constancy of the values of the batch record and the tests of fresh concrete have been improved substantially. The measuring system is almost maintenance-free and the indicator provides measured values of high accuracy.”

In summer 2008, the Olas measuring system was likewise integrated in the control systems of several concrete plants in the region of Freiburg (Germany) of company “Dorner Electronic”. Other users also confirm that this system is an elaborate, innovative and flexible measuring system which may contribute decisively to ensure a high concrete quality when using concrete recycling water in concrete manufacturing.

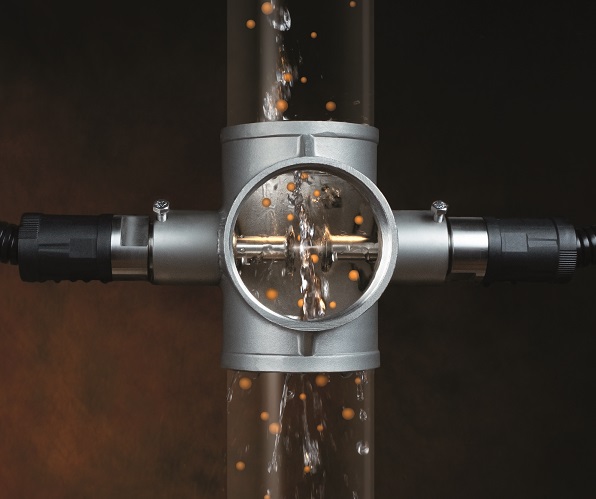

The measuring system

An abstract of the technical details of this measuring system reveals the innovative approaches of this development. The instrument has a settling time of below 40 msec and is still able to cover and indicate measuring light intensities of 1/10,000,000 of the maximum intensity. The internal resolution is even higher. Just in case of high-density media such as concrete recycling water the penetration of measuring light is enormous and the measuring system can demonstrate its strengths. The system comprises a unit of measurement, the actual Olas, and a display and control unit, the Olas touch panel controller (Olas-TPC). Both units are interconnected by an interface. In this way, it is possible to position the unit of measurement far from the display and control unit. (Alternatively, it is also possible to connect the Olas directly with the process control system.) From the unit of measurement two fiber optic cables of a length of up to 20 m with protective covering are led to the measuring point. One fiber optic cable is connected with the optic transmitter and the other one with the receiver. Both cables finally end in the sensor head, which is immersed into the recycling water at a suitable position. By using fiber optic cables the measuring head does not need any kind of electronics and is therefore totally insensitive to electromagnetic interferences. As it is not at all necessary to consider any bulky electronics, the measuring head, moreover, may be set up in a very compact and space-saving way and it is quite easy to install the same. Due to this arrangement the sensitive measuring electronic system is placed outside of the measuring medium and far from heavy current equipment (pumps, agitating machines), making the measuring system permanently robust and extremely fail-safe. As the measuring head is positioned in the suction area of the pump, it is ensured that always the effective density of the residual water added to the manufacturing process is measured. Furthermore, the Olas provides a unique suppression of ambient light. Not only constant light (sunlight, etc.) is suppressed, but also modulated light, for example, the light of a fluorescent lamp. Owing to the high level of ambient light suppression, it is possible to do without any optical blinds. The evaluation and display unit (Olas-TPC) is a redevelopment, too. It is operated through a touch screen and allows easy and well-arranged handling. The calibration curves may be either displayed graphically or as a chart and can be edited. Moreover, a “record” mode may be chosen, which allows to display the measuring signal as it is the case using a transient recorder. Upon request, an external PT100 temperature sensor may be connected to the evaluation and display unit, in order to show the temperature of the measured medium on the shared display. All common standardized signal outputs are available for the evaluation and display unit.

Calibration of the system

It is very easy to calibrate the measuring system. At first, a number of different samples are prepared in the density range of, for instance, 1.000 to 1.150 kg/l, whereas the null method should be effected by a sample consisting of clear water. The semi-automatic calibration procedure of the Olas-TPC allows the direct entry of the calibration points in the simplest way. For this purpose, the measuring head is immersed into the first sample, the measured value is saved automatically and immediately afterwards the reference value of density is entered, which is determined by means of an areometer. Then the procedure is repeated with the other samples. The system calculates the calibration curve automatically from the calibration points through linear interpolation. In this way, it is possible to enter the complete calibration curve with all calibration points just within minutes. Soon after calibration the measuring system is ready for operation and indicates the correct density in kg/l. Now, the measuring signal linearized in this manner can directly be routed to a process control system. When measuring the accuracy of readings can be checked at any time through a manual or automatic, cyclic zero test. This is to be done by simply spraying clear water under high pressure between the transmitter and receiver unit and comparing the measuring signal according to the null method. Any foreign substance jammed in the working beam of the optics would be recognized immediately in this way. On the other hand, the water jet may certainly be also used to clean the optics from foreign substances and sediments. In case of a zero test the entire control of the water jet is done by the Olas-TPC including the extraction of the zero test data of a possibly just carried out signal averaging. Interestingly enough, contaminations or scratches (caused by abrasive media) at the optics do not have hardly any negative impact on the measuring accuracy of the Olas, contrary to classical devices for turbimetric measurement which as well work optically. The reason for this fact is that normally devices for turbimetric measurement work in that transparent media that scratches at the optics definitely absorb much more light than the medium itself. However, applications which the Olas has been designed for are contrariwise: In this case, the measuring media absorbs much more light than contaminations or scratches at the optics. As to be able to exclude even any impact on the measuring accuracy in case of applications in much more transparent media, “aged” optics are available upon request.

Andreas Thiel, Wutöschingen