New production facilities in the Mülheim-Kärlich factory

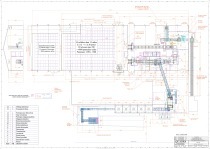

As to be in the position to respond flexibly to the requirements of planners and the building materials trade, Kann invested in their factory located in Mülheim-Kärlich (Germany) and furnished the same with new, up-to-date machinery and equipment for manufacturing high-quality building materials for road, garden and landscape construction efficiently. After a construction period of only five months, the production plant could start operations already in February. The official opening took place in May of this year.

To keep the adjacent residential area free from acoustic impairments, the block making machine was integrated in a new factory building complying with special sound insulation requirements and furnished with up-to-date thermal insulation. The concrete building materials and façade elements required for the construction were supplied by subsidiaries of the Kann Group.

The companies Besser (Emden) and Masa (Andernach) were responsible for the installation and commissioning of the technical machinery and equipment. High-quality plastic boards are used for the production of concrete blocks...