Mechanisms and factors of influence

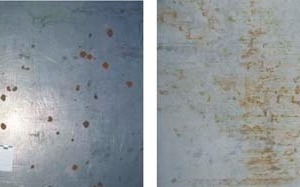

Constructional components of prefabricated concrete are finding increasing application as exposed concrete surfaces due to their economic advantages and high surface quality. However, corrosion of the steel molds in prefabricated components imposes a major limitation on these potential applications. The corrosion products that form on the surface of the mold frames during the comparatively short curing times also transfer to the surface of the prefabricated components, and can only be removed from the concrete and the steel at great expense. In this article the mechanisms of mold corrosion and the influences due to cement chemistry and concrete technology will be explained based on our own experiments with artificial pore-solutions and fresh concrete, and strategies will be derived for prevention of corrosion.

The manufacture of prefabricated concrete components represents an important economic sector within the German building industry. In addition to the economic advantages, there are strong qualitative reasons for the increasing use of prefabricated concrete components. Because of their very good surface texture, prefabricated concrete building components are finding increasing application as exposed concrete surfaces, since the risk of blemishes due to insufficient compaction or of spotting due to uneven application of the demolding agent is significantly less than with concrete poured in situ....