Connection system for waste water treatment plant

Davyhulmne situated in Greater Manchester is one of the biggest and oldest sewage works in England. At present, the British company United Utilities is refurbishing and modernizing the plant at an investment volume worth £ 200 million (equaling € 227 million or US$ 271 million). The plant serves 1.2 million people of the region and additionally deals with wastewater from Trafford Park, the largest industrial park in Europe.

As part of the comprehensive construction project, it is intended to provide the preconditions for building new structures, installing new machinery and introducing new treatment processes. This will enable the future use of new technologies for converting sludge into a high-grade fertilizer and biogas. An essential goal of the construction project is to make the waste water treatment plant cleaner and greener in order to reduce the impact on the environment caused by waste water.

Certified safety

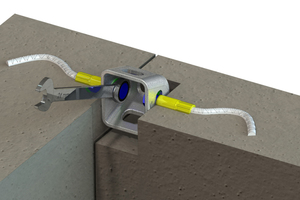

One of England’s leading manufacturers of precast concrete products, CPM Precast Ltd., was awarded a contract to supply accurately fitting box culvert segments for two sewers. The construction engineers were searching for a solution for connecting the precast elements in a fast, reliable and water-tight manner. The fact that there will be traffic areas above the sewer in some sections had to be taken into account, too.

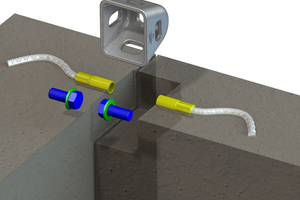

In order to meet these requirements, they tested the use of the products BT-Spannschloss turnbuckle and RubberElast of B. T. Innovation. Even someone working with the products for the first time is able to apply them without any problems – it’s like “plug & play” at the construction site. Screwing of the elements with the BT-Spannschloss and compacting the sealing worked perfectly in the test.

Connecting fast and water-tightly

The two most important requirements imposed on the solution of the connection were to connect the segments in a fast and water-tight manner. The construction engineers were moreover satisfied by the fact that the RubberElast sealing strip ensures long-lasting tightness when in contact with aggressive media such as sludge. This is confirmed by the test certificates granted by building authorities.

The new connection channel is nearly 100 m long. A total of 80 precast concrete elements – box culvert segments in the dimensions of 4 m x 3 m x 1.5 m (height x width x length) were used up in building. Corresponding to the culvert dimensions, turnbuckles in two sizes were used: 160 of type M20 and 124 of type M16. The companies involved were impressed by the efficiency of the connection system. Despite adverse circumstances, such as heavy rain, the complete assembly process was shortened and completed within six days.