Hybrid precast hybrid building overcomes limitations

The building H7 at the city port in Münster, Germany, extends between the organic cheese plant and the company grounds of Cronos GmbH. The 7-story hybrid-construction building is the highest building of its kind in North Rhine/Westphalia. The land building code currently in force permits flammable materials as structural members only for buildings with a maximum of three stories. With the hybrid structural concept – here, timber combined with reinforced concrete – however, enables intelligent conformity with this regulation.

Ecological approach for multi-story structures

The office and administrative building, erected by Desrad Immobilien GmbH, based on the design by the architect Andreas Heupel, sets high standards for sustainability and energy efficiency. Employing high-quality, low-emission materials, for example, enabled realization of a high environmental-compatibility building standard. The contract for construction was awarded to local companies and processors: for example, the Munsterland project construction specialist Brüninghoff in Heiden, Germany.

Planning is for a total of eleven rental units averaging 350 m², on a rentable area of 4,340 m².

Hybrid timber/reinforced-concrete construction

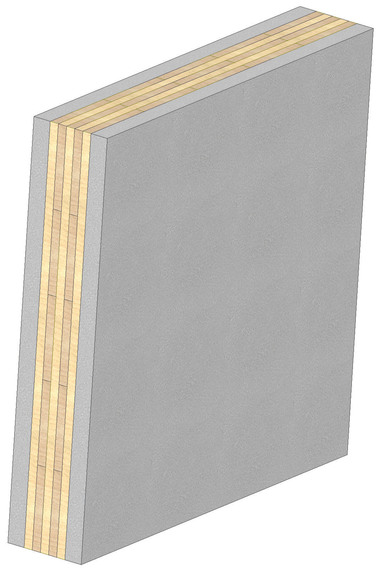

The underground garage and the ground floor were implemented as conventional reinforced-concrete construction with structural concrete walls, columns, and beams. The central access core was constructed with climbing formwork. Reinforced-concrete columns and reinforced-concrete beams were installed from the first floor upward. The concrete columns span 8.10 m. The loadbearing structure is supported by a grid of 1.35 m. The intermediate floors are composite timber-concrete floors. The laminated timber with a cross-section of 24 x 26 cm is bolted to a reinforced-concrete slab 12 cm thick to form a hybrid floor here. The external walls and parts of the loadbearing structure were executed in timber. The wall elements, the semi-precast beams, and the composite timber-concrete floors were prefabricated by the company Brüninghoff.

Project-specific logistics and fire-protection design

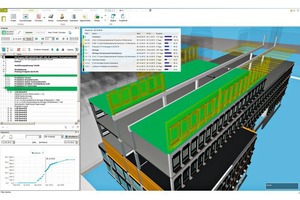

The basis for the innovative logistics planning conceived by Brüninghoff for the H7 in Münster was building modelling based on BIM. Not only the physical and functional properties are managed in the model, but reference is provided to all project-relevant data established as well.

Fire protection for the loadbearing structure of the H7, which consists primarily of timber, was here of special concern. It required a deviation from the building code of the federal state of North Rhine-Westphalia that permits a maximum of three stories for structural timber buildings. For reason of fire safety, no timber was used for the room-enclosing members of the fire-escape staircase and the fire walls.

In the basement level of the H7, use of timber was also not possible, due to contact with the ground. The stiffening frame to counter horizontal loading of the building could likewise be implemented more effectively with a reinforced-concrete core.