Formwork handling in the precast factory

According to the manufacturer, as an alternative to using robots for the erection and removal of the formwork, B.T. Innovation GmbH has designed a powerful and precise formwork handling device being an effortless and comfortable wire rope lifting device at a smooth-running crane system.

The lift control of the same is effected directly, precisely and intelligently by simple movements of the hand with the aid of a control lever. A positive locking load suspension device enables handling formwork of various shapes and sizes in an easy and simple way. Varying lifting heights achieve a maximum carrying capacity of 80 kgs; further load levels are available as an option.

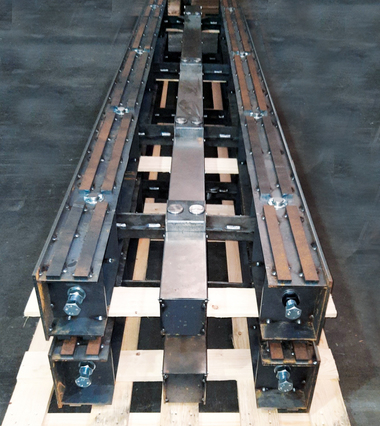

Lightweight shuttering carrier systems

With Multiform and Flyframe B.T. Innovation has brought two shuttering systems to the market which enable above all easy handling and precise working owing to their low weight. In this way, working time and material required for formwork construction are reduced. Magnets and formwork are not connected in a fixed manner, and it is possible to realize formwork heights of 100 up to 400 mm (Flyframe) and 100 up to 600 mm (Multiform) respectively.

U profiles for floor slabs and wall elements

The Magdeburg-based company also offers shuttering systems for precast floor slabs and double walls. These U profiles are available in various designs and dimensions. Besides the version without integrated magnets, these are magnet designs with control button or Magswing technology.