High-tech laser projection systems for precast concrete production

The company SL-Laser GmbH of Traunreut (Germany) meets their customers‘ requirements for more speed, higher precision as well as optimized costs and production processes with their laser measurement systems. The projection systems that may be applied universally are used all over the world, amongst others, in the building and construction industry and for the production of precast components made of concrete. Due to the ease of use, the fast set-up time and ruggedness, the devices are indispensable tools for many companies.

ProDirector for the precast concrete industry

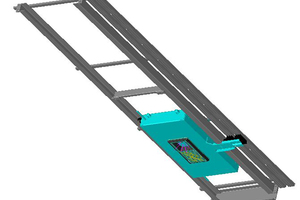

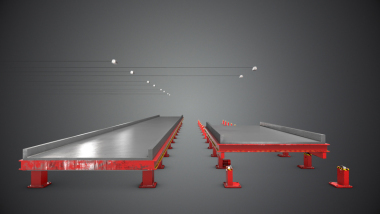

The computer-controlled laser system with the corresponding software allows to transfer working plans and measuring points even for large-scale or angled mounting surfaces accurately as well as in a time and cost saving way. In the field of precast concrete construction, the firmly fixed ProDirector XS enables exact positioning of formwork, embedded parts and reinforcement. The lasers in the precast plants save the users on site the time-consuming manual measurement of the positions for the formwork, empty pipes and built-in components. Directly 1: 1 from the CAD, the contours are projected on the tables. The projection makes it possible for the workers on site to use the components immediately. The installation of the laser is fix above the table or on rails for long tables.

In the first variant of the installation, the laser is working on a carousel table system. The tables are moving under the laser place and the palette is under the laser. Depending on the program, different elements are projected. Formwork, built-in parts, magnetic lines, shutterings. These elements are projectable on different heights. Either the height is stored with the component or it is manually entered from the Laserpilot software, from SL Laser, via a dialog box or can be stored as a function button in the Laserpilot interface. The customer has the option to put these functions on the remote control.

The operation of a laser as a rail system is similar. In that case, the laser moves from position to position along the long table. SL Lasers experience in that case is unique and some of the customers uses that system with a length of 120m rails.

Software imports all popular formats

The advantage of this system is that a complete table can be predefined. The definition of the parts are made in a CAD-System and the laser can process project by project. Each stop at specific position for the laser will project all the elements that are used. These elements are on different layers, so that even in the case with a remote control or via the surface of the Laserpilot software the different components are projected.

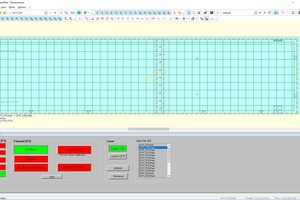

The software imports all popular formats for projection. That could be DXF, DWG, ULB, HPGL. Customer-specific data formats are tested in-house and discussed with customer about the option of use that specific format with the Laserpilot Software. The laser systems also work together with known control systems.

Laserpilot software for every application

The Laserpilot software makes it possible to generate a suitable surface for every application in the precast industry. As required, the modifications are discussed with the customer and placed on the software interface. This can be from calling the file, calibrating, rotating, turning, mirroring, moving in the x and y directions, as well as projecting at a different z-height. Projecting at a different Z-height has the advantage that the line on the upper edge of a stand or other component is better visible than at height 0, since shadowing may occur at height 0.

In addition, the angle of the component can also be taken into account. Many of these functions can also be placed on the remote control so that the user can use these functions with one „click“.