Indonesian manufacturer PT. Rekagunatek Persada extends its range of services

The Indonesian Company PT. Rekagunatek Persada decided to set up a plant for the production of precast concrete parts for housing and building construction. After visiting several reference plants in Asia and Europe, the company decided to collaborate with one of the major global plant specialists, Weckenmann Anlagentechnik GmbH & Co. KG from Germany.

Based in the Indonesian capital Jakarta, PT. Rekagunatek Persada is a subsidiary of PT Indonesia Pondasi Raya, Indonesia‘s leading specialist foundation engineering company. The company decided to set up a plant for the production of precast concrete parts for housing and building construction to expand its range of services in this area.

After having already been involved in the foundation work of many of the existing building projects and already having produced precast concrete parts for civil engineering in the past, the precast concrete parts to be produced now should be of particularly high architectural and structural quality for high-rise residential housing.

The high demand for these products and services was driven by the numerous construction projects planned in Greater Jakarta, which were in the implementation and planning stages.

After visiting several reference plants in Asia and Europe, the company decided to collaborate with one of the major global plant specialists, Weckenmann Anlagentechnik GmbH & Co. KG from Germany. Weckenmann convinced with its broad production portfolio engineered and made in Germany.

Investment in a central transfer table system

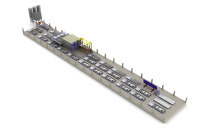

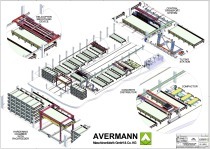

The decision to build a central transfer table system was based on the special requirements for production flexibility. The investment in the central transfer table system for the production of solid wall panels represents the first stage of the complex production plant at a newly developed production site.

Approximately 700 m² of wall panels can be produced per shift on a total of 22 shuttering pallets with a gross production area of 4.3 x 12 metres. The wall panels are solid partition walls as well as façade elements with partly architecturally structured fair-faced concrete surfaces. The formwork surfaces are precision machined to produce perfectly smooth and level surfaces.

The design of the central transfer table system concept allows different lengths of stay in the individual workstations, without shuttering pallets with a longer processing time impeding the material flow of pallets with a shorter processing time, unlike in a conventional circulation system. Overall, the system is equipped with 29 working and curing positions. These are all on one work level.

Reinforcement cage production is currently still done offline. The reinforcement cages are produced using standard mats and placed in the shuttering pallets. Twenty work positions are provided for curing and surface finishing.

The freely selectable access work positions for the simultaneous curing and surface finishing allows the surface to be finished with a helicopter trowelling machine at the technologically correct curing time of the produced concrete elements, without the pallets having to be moved again during the curing time. The helicopter trowelling machine moves over the entire curing range of 20 positions.

A special feature of this concept is the circulation running parallel to the central transfer table between the following positions:

Pre-stripping

Stripping the end of the shuttering pallet

Stripping

Cleaning and plotting

As these processes can take place independently of the operation of the central transfer table, the operation of the central transfer table is accelerated without restricting the flexibility of the system.

Shuttering pallets with side rails

The shuttering pallets are fitted with side rails that are permanently mounted on one-side, but that can be replaced by unscrewing them. The side rails are designed to act as a levelling mechanism for the bull float of the concrete spreader at the top so that an exact level can be achieved by screeding and smoothing the elements.

Different formwork heights are made possible by reusable shuttering rails, and different formwork contours by magnetically adhering moulding profiles. The load on the shuttering pallets is up to 1,000 kg/m², which means up to 400 mm thick elements, can be manufactured.

M series shuttering system in use

The shuttering profiles as well as the recesses for door and window installations are produced by the proven M series shuttering system with integrated switchable magnets.

This shuttering system is individually equipped with the required profiles for the formation of the grouting and abutment surfaces as per the customer‘s requirements. Depending on the type of production, telescopic extension profiles are provided to adjust the individual lengths of the shuttering profiles.

The production data is transferred from the CAD system via a DXF data interface. The WAvision light master computer program is used for the production planning and optimisation of the pallet loading. The production data is transferred to the cleaning-plotting-oiling machine by means of a USB stick.

The cleaning-plotting-oiling machine is a multifunction machine, which has the following functions:

Cleaning the shuttering surfaces

Plotting the production data 1:1 on the formwork table surface

Oiling the pallet by applying forming oil agents to the formwork surface

As the shuttering pallet passes through this workstation, preparation for the next production run is done quickly and with controlled quality, all in one go.

Integrated concrete batching plant

A concrete batching plant integrated in the system concept produces fresh concrete. The bucket conveyor spreads the concrete required. This is controlled by a control panel on the concrete spreader. Using a communication interface to control the process, the exact amount of concrete needed is prepared in the concrete batching plant, ensuring a just-in-time concrete supply to process the concrete without loss of quality, which is very important in the prevailing temperatures of this tropical climate.

A half-gantry concrete spreader with a transversely slidable application container processes the concrete through specific spreading of the concrete. The concrete spreader with spiked roller discharge and eight slides allows the screeding of the wall panels directly during concreting. The concrete is compacted by means of a combined high-frequency low-frequency vibrating/shaking station while concreting is taking place. Combining these two procedures enables optimum compaction in different floor slabs and concrete consistencies.

Summary

The operated plant allows excellent production flexibility due to the material flow design of the central transfer table. The shuttering pallets with two load levels (500 kg/m², 1,000 kg/m²) in combination with the flexible shuttering system are equipped for future expansion of the product range.

The basic automation of the system enables high-quality production with a manageable investment budget. The production layout allows the expansion of production capacities. The system concept is designed to be ready to increase productivity even more by retrofitting a shuttering robot.