Innovation: CBS building system for high-quality living space

The CBS technology is based on and made up of two construction material components:

a slender lightweight structural steel framework consisting of 1 mm to 2 mm thick cold-formed galvanized sheet steel

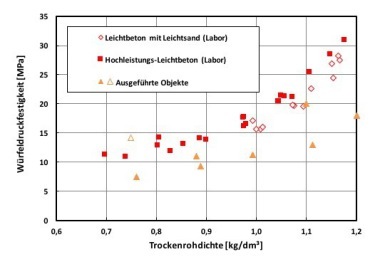

lightweight concrete with a bulk density of 400 kg/m³ to 1,200 kg/m³, with higher bulk densities being possible

According to DIN EN 1045, concrete with a bulk density of between 800 kg/m³ and > 2,000 kg/m³ is referred to as lightweight concrete. By comparison: “standard” concrete has a bulk density ranging from 2,000 kg/m³ to 2,600 kg/m³. Technically, the lower limit for lightweight concretes is currently around 350 kg/m³; normatively, the lower limit is around 400 kg/m³. Aggregates of high porosity are used to achieve these values. This means that the aggregates have a high percentage of ultrafine air voids in each grain (up to 85 % by volume).

The lightweight structural steel framework is completely filled and enclosed by bound filling material, thus creating a compound element with high load-bearing capacity and low thermal conductivity. The currently used filling material is a cement-bound lightweight concrete according to DIN EN 1520. This no-fines lightweight concrete on the basis of expanded clay is a highly ecological base material and generates a positive ecological balance, which also has a positive effect on the life-cycle analysis. The structural system in the wall and ceiling elements is characterized by thin-walled, 1 mm thick supporting bars that are connected by 2 mm thick U profiles, each consisting of cold-formed and galvanized profiles with special profile geometry. The technical approval requirement for the building system follows from the active use of the enclosing lightweight concrete as stabilizing element as well as transfer of the normal forces. The technical approval and design of the lightweight steel profiles are premised on this finding. The basis is DIN EN 1993-1-3 (formerly DASt [German Committee for Steel Construction] guideline 016). The gross cross section of the profiles is maintained while simultaneously assuming that the supporting bars retain their shape due to restraint action. Foam concrete is used as insulation material, which completely eliminates the need for ETICS. As the lightweight concrete is self-compacting without any external forces acting on it for compaction purposes (vibration method), it is possible for all additional building measures to be completed at the plant.

The CBS system (Compound Building System) combines the disruptive technology of a start-up company with the experience of a real estate project designer. The CBS building system enables industrial series production of cost-effective building elements that can be individually adapted to market requirements. Similar to automotive construction, a reduced number of components with a highdegree of combinations covers construction with numerous creative and design options.

Conclusion

CBS believes this technology to have the potential to actively influence the construction sector by reducing the price level and shortening the production process. According to the manufacturer, the technology is also significantly more resource-efficient compared to the conventional production method, while at the same time ensuring an individual character due to permitting a free floor plan design.

The plant commenced production in October 2021 and is already supplying building elements for multi-family and single-family homes, garages, self-storage parks and privacy walls.

The technology has been registered under European patent number EP 3 574 160 B1. The general type approval has been granted under number Z-14.5-883.

CONTACT

CBS Home GmbH

Im Bettinger 17

78652 Deißlingen-Lauffen/Germany

+49 7726 93872-240