Innovation: New Schöck Isokorb ID element

Following the principle of “first the shell construction, then the balcony”, the new Schöck Isokorb ID element allows the subsequent installation of balconies in new building construction. This completely revolutionizes the construction process. The balconies are manufactured at the precast concrete plant as complete precast elements with integrated Schöck Isokorb, and then they are delivered to the construction site. After completion of the shell construction works, the balcony is connected to the floor slab by means of an additional Isokorb element.

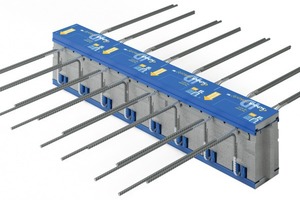

In this regard, the proven Schöck Isokorb technology ensures, of course, energy efficiency and safe load-bearing structures, as usual. The Schöck Isokorb ID consists of the components Schöck Isokorb ID and Schöck IDock, which comprises the edge and floor slab element.

All of the advantages of the new Schöck

Isokorb ID at a glance

Flexible: The Schöck Isokorb ID system allows the subsequent connection of precast concrete balconies, galleries or canopies to new building structures. The balcony slab and floor slab are manufactured independently of each other – which means more flexibility for the precast concrete plant and construction company.

Efficient: The subsequent installation of balconies minimizes construction time and construction costs: The assembly time is reduced and large-area formwork can be used without restrictions. Moreover, façade elements can be mounted and completed earlier.

Fast: The Schöck Isokorb IS system cuts the costs for temporary supports of the balconies considerably: The precast concrete balconies are completely self-supporting and loadable already 48 hours after installation.

Safe: The Schöck Isokorb ID avoids subsequent costs and elaborate repair works: Since the balcony is only installed subsequently, it cannot be damaged or contaminated during shell construction.

Dr.-Ing. F.-H. Schlüter has given his expert opinion on the Schöck Isokorb ID and the technical approval is available.