Independent installation during shell construction with Isokorb ID

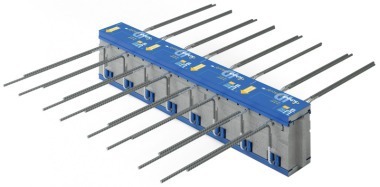

At the trade fair BAU held in Munich, Schöck Bauteile GmbH presented the new Isokorb ID for subsequent installation of precast concrete components, such as balconies, in new building construction. The cantilever or supported balcony can be mounted at the end of the shell construction prior to installing the windows. The system solution consists of three components in total: An edge element, a floor element and the Schöck Isokorb ID element. Well-proven Isokorb technology combines high energy efficiency with a reliable supporting structure in terms of statics.

The Schöck Isokorb ID system allows the subsequent connection of precast concrete balconies, galleries or canopies to the shell skeleton. Its special feature: Shell construction works and installation of the precast component can be carried out independently of each other. This changes the entire construction workflow, providing new possibilities for processors. In this way, the entire conventional kind of installing balconies with concrete can be reduced from previously several weeks to a total of three days. Thus, the new system concept reduces the time previously needed for elaborate temporary supports on several floors. Equipment installation and assembly times are reduced considerably. The individual concrete elements are completely self-supporting and loadable already 48 hours after installation. Now, it is easy to mount and finish façade elements, and this works can even be started earlier in the construction process.

Simple and safe processing

The principle of processing is simple and safe: At first, the edge element and the floor element are integrated into the reinforcement placed on the side of the floor right at the point where the precast balcony is to be connected. Then, the floor can be cast. The recess units of the floor element as well as the edge element are removed prior to inserting the Schöck Isokorb ID element. In this way, the recesses remain in the floor for later installation of the balcony slab with integrated Schöck Isokorb ID. For this purpose, the precast concrete balcony is positioned into the opening provided. The recesses in the floor are subsequently filled with a grout concrete. Consequently, the reinforced-concrete balcony slab can be cast during the shell construction at a later point in time than casting of the floor.

Saving costs through optimized construction processes

It is thus possible to optimize and accelerate the entire construction process, the construction period as well as the respective construction costs. This relates, in particular, to the costs of the supporting scaffold. The crane can be used optimally on the site, shortening the construction period. The system, moreover, allows unrestricted use of large-area formwork. Furthermore, damaging the clean and sensitive elements during shell construction is avoided by subsequent fastening of the precast concrete elements. Subsequent costs caused by elaborate repair work can be eliminated. An upstream production of balcony slabs with integrated Isokorb element at the precast concrete plant is moreover flexible in time.

Versatile applications

The new Isokorb ID range allows realizing conventional balcony solutions in simplified precast concrete construction. Isokorb type IDK and Isokorb type IDKXT are used for cantilever balconies. The types Isokorb IDQ and Isokorb IDYXT enable the connection of supported balconies with thermal break. They are suitable for four different load-bearing capacities each as well as a balconies thickness of up to 250 mm. The Isokorb ID system can be used for reinforced-concrete floors with or without edge beam. The national technical approval of the German Institute of Construction Technology (DIBt) based in Berlin will be granted at the beginning of this year. The product will be available as of July 2015.