Innovations and system optimizations at BAU 2017

At Bau 2017 in Munich, from 16 to 21 January 2017, at stand 408 in Hall A1, Pfeifer Seil- und Hebetechnik GmbH will showcase its innovations, further developments, and system optimization products.

Fixing system assortment for inclined columns

The Pfeifer fixing system for inclined columns that will be presented at Bau 2017 rounds out the company’s product line for secure and simple fixing of inclined columns to double-wall elements. For the erection of precast wall panels, and especially double-wall elements, a problem that was regularly encountered formerly was to find approved means of anchorage. The main reason for difficulties here is the very thin walls of the elements. Finding anchorage solutions among the existing devices for wall thicknesses up to 50 mm previously posed considerable problems where concrete anchorages were involved. Safe and secure application of the existing plastic systems is also a problem not to be neglected, since excessive tightening torques can lead to failure of the threads.

With the inclined column anchors MoFi12 and 16, Pfeifer now has an approved anchorage system in its program that solves these problems. The anchorage system is rounded out by the Pfeifer-ConFi matching concrete bolts for the column shoes of the inclined columns.

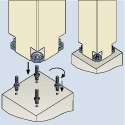

PCC column shoe system for simple bolting

The Pfeifer PCC column shoe system enables loadbearing connection of columns and foundations and/or columns to columns simply by bolting. In this way, foundations and columns can be separated during transport and erection. The full loadbearing capacity is already ensured without casting and is independent of any other boundary conditions.

The foundation anchors into the foundation are installed either at the site or in the precast plant, with installation of the column shoes always in the precast plant. This ensures separate transport of the elements to the construction site under optimized logistics conditions. Erection takes then place by simply bolting. The connection is instantly loadbearing. Complex propping measures are not required.

New design of VS rails and VS strips

In addition to connections to ensure stability, for which only officially approved products such as the VS-ISI system may be used, there is now as before a wide range of so-called structural connections. These generally involve connection details to which no design loads are allocated.

For connections of this kind, the following products were redesigned: T50 VS rails and T20 VS strips for structural wall tee-joint or column-wall connection as well as VS rails W50 for establishing structural connections among walls. The advantages for users were the systematic arrangement of the loops, the flexible number of loops from 2-7, and the optimized grouting channel for reduced mortar consumption.

System extension of the Pfeifer-WK system

In the context of a more market-oriented revision of the WK system, several new models for installation into thin wall panels, slender beams, and sandwich elements have been developed.

These include additional models in the form of WK bar anchors, crimped WK bar anchors, and WK anchors in optimized length. All varieties within the WK system are the preferred choice for installation in thin precast elements. The Pfeifer-developed shaft for the WM anchors, with long shape, ensures gentle load transmission, especially for low element thicknesses. For elements with a higher percentage of reinforcement, use of the WK bar anchor is recommended, since its straight ends considerably facilitate threading into the existing reinforcement in the element.

Pfeifer angular loop as reliable work equipment

Harmonization of European standards and regulations has brought about many changes in recent years. For transport anchors, Machinery Directive 2006/42/EC has already been established since 2009 as mandatory basis for their development, construction, and use. For comparable application of verifications, the VDI/BV-BS 6205 code of practice with the title “Transport anchors and transport anchor systems for precast parts” was introduced in 2012. It requires manufacturers of transport anchors to take into consideration significant dangers in designing a transport anchor system: e.g., the risks of toppling, falling, or dangerous pendulum movements. On the users’ side, companies are forbidden by labor health and safety legislation to use unsafe work equipment.

A completely developed state-of-the product such as the angular loop from Pfeifer meets all of these legal requirements and satisfies all valid regulations. An employer who uses a Pfeifer transport anchor is able, both formally and in practice, to provide its employees and customers a safe product in the sense of the Machinery Directive and to demonstrate compliance by means of relevant documents.