New FastKick hardening accelerators for concrete

With MC-FastKick, MC Bau-chemie has developed a new product family of hardening accelerators upgraded with the very latest MC polymer technology. They provide concrete with very good processing and application properties, including high early strength values. Their mode of action really does give concrete a kick by significantly accelerating the hardening process, thus greatly reducing cycle times in precast operations and also making possible shorter hardening times during wintertime construction.

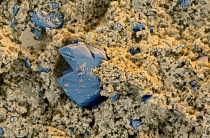

The new PCEs (polycarboxylate ethers) which MC has formulated for MC-FastKick have a positive influence on crystal growth in the calciumsilicate-hydrate phases within the concrete. This results in a significant increase in the crystallisation rate and thus substantially higher early strength values – but without negatively influencing the other concrete properties. The product family has two members at the moment: MC-FastKick 111 can be used for concrete and reinforced concrete, and MC-FastKick 105 for concrete, reinforced concrete and prestressed concrete – in other words, virtually all types.

Advantages for precasters and winter construction

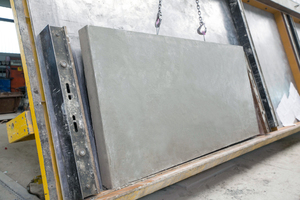

MC-FastKick offers precast concrete producers enormous benefits, as their formulations reach the requisite strength necessary for stripping/demolding substantially faster, thus increasing turnaround rates. The acceleration effect is largely dependent on the reactivity of the cement type used. The period for maximum acceleration in the case of CEM I lies in the range of six to 12 hours, with CEM II it is roughly eight to 16 hours and with CEM III it is approximately ten to 20 hours. Aside from applications in precast concrete production, MC-FastKick is also suitable for winter construction applications, as it will compensate for the longer hardening times that would otherwise result from the reduced temperatures.

In addition to the increased strength values after 24 hours, MC‘s new hardening accelerators also allow slightly increased 28-day strength values. The special activation mechanism in the admixture causes the concrete matrix to become more dense and thus to achieve higher strength levels more quickly.

Substantial plasticizing effect

In combination with a PCE-based plasticizer, MC-FastKick offers not only the increase in early strength values but also an extension in the concrete’s consistency by up to two classes, thus greatly improving flowability without affecting stiffening behavior. Consequently, the quantity of plasticizers used and/or the water content can be reduced, causing the water/cement ratio to decrease and yielding savings in cement used. This helps to cut costs and also to protect the environment.