Production of reinforcement for AAC elements

The product line of Eurobend GmbH includes sustainable solutions and a wide range of automatic mesh welding and reinforcing steel processing machines for the greatest majority of precast concrete applications. Special solutions for the production of welded wire mesh and reinforcement systems for the aerated concrete industry are offered and are successfully used by leading AAC plants worldwide.

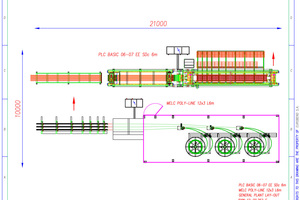

For the reinforcement mesh production various, tailor-made, cost-effective systems are used, depending on the productivity requirements of each AAC plant starting from the entry-level models for small and medium-sized productivities to the high-performance systems of AAC production lines. On the PLR Basic XE series, the line wires are manually inserted directly into the welding line. The cross wire is fed in via an automatic magazine. The straight bars are produced by a rotor straightener, model MELC Monoline, with a maintenance-free 5G rotor (patent).

New high end spacer system

In the high-performance systems, the AAC production lines, the wire mesh is produced by a PLC Basic EE Fse welding machine, with the line wires being automatically fed into the welding line via a line wire preloading carrier unit. The cross wire is fed in via an automatic cross wire feeding magazine.

Depending on the product flow at the plant different solutions are offered for the stacking and discharging of the finished mesh bundles: stacking units and roller conveyors for forwarding the bundles in production direction are available, or chain conveyors which distribute the mesh sideways. In these AAC production lines, the straight bars are produced by multiline rotor straightening machines of the MELC Polyline series with 5G maintenance-free rotors that work simultaneously.

Even higher productivities can be achieved with mesh welding machines that work directly from coil. Together with these systems, Eurobend offers a new, high end spacer system for assembling the mesh into basket for the aerated concrete form. The spacers for the baskets are produced directly at the assembly station (from coil) and then placed and welded automatically to the mesh to form the basket.