Teka celebrates its anniversary – 60 years of Teka Maschinenbau GmbH

This year, Teka Maschinenbau GmbH based in Edenkoben in the German Palatinate region is celebrating its 60th anniversary. “This long and successful endeavor would not have been possible without our loyal customers, reliable suppliers, and experienced partners and employees,” says Markus Gartner, managing director of Teka Maschinenbau GmbH. “Working on ensuring our continued success is a daily task, and the way we do business has always been based on an outstanding customer service. Many thanks for your trust and many years of loyalty,” Gartner comments.

Teka Maschinenbau GmbH remains a reliable partner of its national and international customers even amid the Covid-19 pandemic. During the crisis, the company has always ensured timely spares supply to the large number of concrete plants served by the business, as well as their reliable installation and assembly. “Teka is exceedingly well-prepared to respond to the challenging times that lie ahead in a quick, flexible and consistent manner and to provide a top-class service to the concrete plants operated by our customers,” Gartner adds.

Plant upgrades and conversions, new production lines

During the past 60 years, many concrete producers got convinced of the top-class performance of Teka. The company looks back to a long history of producing high-performance mixers for the concrete industry and specializing in plant upgrades and conversions as well as new production lines. BFT International also regularly publishes articles reporting on the projects successfully completed by the business based in the German Palatinate region. Teka can build upon an extensive array of knowledge and expertise. The company’s trump card are its experienced people who have usually worked with Teka for many years and are thus able to provide comprehensive consultancy and support to the company’s customer base when it comes to their individual projects. Accordingly, each project is designed and analyzed in response to the specific requirements defined by the customer in order to jointly identify the best solution for the operator of the plant.

High-performance mixers for national and international markets

Teka turbine and planetary mixers are preferably installed in plant upgrades and new production lines. In the past few years, a large number of Teka high-performance mixers were delivered to concrete producers in Germany and worldwide. The Teka range is primarily used for producing high-quality or challenging concrete mixes or manufacturing custom products.

In the ready-mix sector, too, the specifications for concrete become more and more demanding, which is why Teka high-performance mixers are also increasingly being used in this part of the industry. Nowadays, many ready-mix plants across the globe successfully use Teka mixers for producing self-compacting and other custom concrete grades.

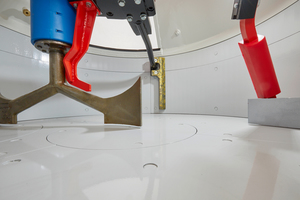

THT turbine mixers ensure unrivaled product diversity

Meanwhile, the innovative, patented mixing technology on which the Teka THT turbine mixer range is based has been installed in a large number of concrete plants that manufacture high-quality products. The THT turbine mixer range is primarily used for complex jobs, including, for instance, the production of face mixes, colored, fiber-reinforced and polymer concrete, as well as self-compacting and ultra-high-performance concrete. One of its major advantages compared to other types of mixers is the option to also process minimum quantities for custom products. “This is where our turbine mixer really hits its stride,” Gartner comments. The patented mixing turbine thus ensures an unrivaled diversity of concrete products by providing the option of processing, in a single mixer, a wide range of different mix designs and batch sizes, including smallest quantities.

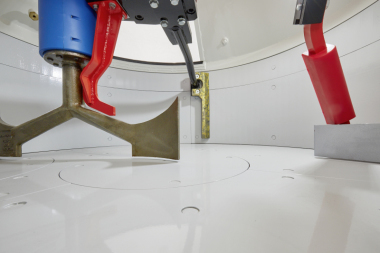

Planetary mixers with continuous directional change

Teka high-performance planetary mixers are also exceedingly popular with concrete businesses both in Germany and abroad. The countercurrent mixing principle, where the mixing stars rotate in opposite directions and thus feed material to each other, leads to a continuous directional change and a “collision effect” of the mixed material that ensures high-intensity mixing within a very short time. In addition, the mixing stars rotate about different radii so that they engage with each other in the center of the mixing vessel, just like toothed gears, thus perfectly covering the entire bottom without leaving any zones unmixed.

The planetary mixer range has become the preferred high-performance mixing solution at the most renowned concrete plants worldwide thanks to the benefits of this mixing technology in conjunction with exceedingly low operating and maintenance costs and a very low degree of wear, which is mainly due to the custom design of the mixing arms and the deliberately small number of mixing tools.

In-house testing facility in Edenkoben

For many reputable manufacturers of concrete products, Teka turbine and planetary mixers have meanwhile become a tried-and-tested solution that is also suitable for a wide array of different (challenging) mix designs as well as for 24/7 operation. These high-performance mixers are generally well suited to completing complex mixing jobs and widely different batch sizes. The company operating the plant will thus be able to manufacture a diverse array of concrete products. Concrete producers can carry out mixing tests and personally monitor the outstanding performance of the high-performance mixer range on the in-house testing facility that Teka operates at its plant in Edenkoben in the German Palatinate region.

“Many thanks”

“On the occasion of our 60th anniversary, we would like to make sure to thank all our esteemed loyal customers, suppliers and partners both in Germany and abroad for their support and close collaboration over these many successful years. The service we provide to our customers and our successful collaboration are at the very heart of our business. Going forward, our customers can rely on Teka Maschinenbau GmbH remaining their experienced, reliable and trusted partner. You can count on us,” Gartner says.