SCC and state-of-the-art magnet technology put the spotlight on battery formwork

The BFT’s editorial team was quite surprised when, instead of the man in his late fifties they had expected judging by his voice on the telephone, an 80-year-old but nevertheless extremely spry gentleman introduced himself in the reception area of his company. Dipl.-Ing. Gerd Kinast founded Kinast Maschinensysteme GmbH in the town of Eilenburg near Leipzig in 1998, and still manages it today: “Today, we are active worldwide in plant and special-purpose machinery manufacture. Our expertise lies in manufacturing plants for the production of precast concrete elements. Our flat hierarchy and our well-trained and highly motivated staff enable us to develop, design and manufacture complex plants within an extremely short period of time and at competitive prices. We use state-of-the-art 3D design methods and manufacturing processes, and also cooperate with selected partners. Due to the use of self-compacting concrete (SCC) and state-of-the-art magnet technology, we are therefore well on our way to making battery formwork ‘presentable’ again, thus arousing the curiosity of potential customers.”

Making battery formwork “presentable” again

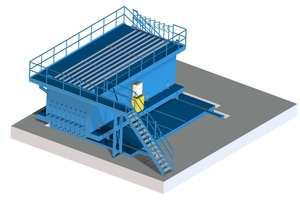

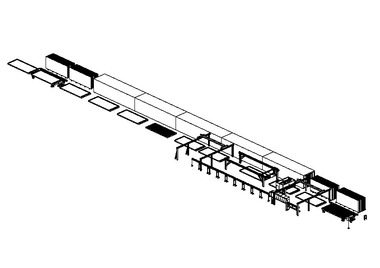

The list of successfully completed customer reference projects is, indeed, long – whether in the immediate vicinity, in Saxony or Thuringia, whether in Sweden, in Abu Dhabi or in Oman: battery units made by Kinast have found their way to numerous countries. Upon request, Kinast Maschinensysteme can set up a battery unit as an on-site facility within just 3 to 5 days. In addition, complete circulation systems, tilting tables and formwork systems for bar elements as well as special formwork and accessories are manufactured in the approx. 1,750-m² large production facility, complemented by steel structures such as platforms, staircases, railings and landings.

The company is currently manufacturing a battery unit for a Romanian precast producer; work is well advanced and delivery is scheduled to take place shortly.

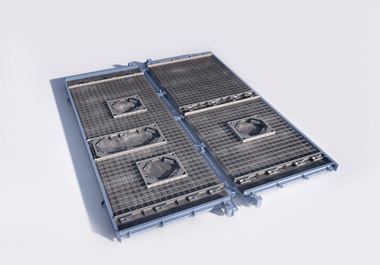

In yet another successfully completed customer project, two special battery units for the production of ready-mixed concrete loggia slabs (Fig. 6), which allow quick modification and relocation, were delivered to Mischek Systembau GmbH, an Austrian subsidiary of Strabag AG.

Kinast only recently supplied Brüninghoff GmbH & Co. KG based in Heiden in the Münster region, a leading manufacturer of hybrid timber-concrete elements (Fig. 7; for a company introduction of Brüninghoff, see BFT issue 1/2023, p. 40/41).

Also for Max Bögl Group, one of the largest construction companies in the German construction industry, a battery formwork was delivered to one of its sites in Gera (Fig. 8/9).

The system offers numerous advantages

“The numerous advantages offered by this system include a closed mold bottom but also channels for guides and cylinders to provide access to the chambers. With an opening width of 1.50 m, our battery units can be opened exceptionally wide to allow operation using forklift trucks of various sizes or the installation of pipes. Laser technology enables us to also achieve remarkable accuracies of +/- 1 mm,” Gerd Kinast continues.

The “battery unit made by Kinast” comprises the following features:

closed drive-on base frame consisting of individual segments

bulkhead walls with dual trolleys for improved stability

travel distance of the mobile tensioning wall of 1,500 mm independent of the package length

motion cylinder integrated in the base frame

mobile tensioning wall with four bottom-mounted and two top-mounted hydraulic-mechanical clamping units

the mobile tensioning wall is adjusted to the package length by means of a ratchet wrench

the Kinast battery unit forms a closed system

assembly is completed within 3-5 working days by two workers depending on size

in standard use, the base frame is set in concrete, and the upper edge of the base frame is at the same level as the building floor

a reinforced-concrete slab with a thickness of 200 mm to 250 mm is required for use on larger construction sites and to enable subsequent relocation

No insulation required

Gerd Kinast explains: “The bottom insulation elements have their own trolleys, so that there are no limits to the element thicknesses. For increased variability, the bottom insulation elements and end walls can be designed as a supporting structure. The end walls are connected to the bulkhead wall via coupling links allowing precision adjustment within the millimeter range. Due to the parallel linkage, the end walls are self-demolding when removing the element.”

The package is opened and closed via hooks mounted on the end walls. The hooks are connected by means of a continuous shaft, which allows them to be operated by a single person.

Insulation of the battery formwork is not required: the heat of hydration heats the concrete element to up to 50°C and is transferred to the bulkhead walls. Contrary to the opinion sometimes voiced that the walls also require cooling, Kinast is sure that the temperature in the working chamber drops relatively quickly simply by opening the chamber, which is very wide at 1,500 mm.

“We also cannot corroborate the assumption that the concrete segregates when dropped from a great height. On a battery unit delivered around four years ago, we have already been able to prove that there are no shuttering changes in the lower section.”

The energy requirement of a battery formwork is very low, as all movements are effected hydraulically. A power unit with an output of 5.5 kW is installed on the mobile tensioning wall for this purpose, which is in operation for approx. 2 to 3 hours during a full cycle.

For concrete pouring, a hopper placed across the bulkhead walls has proven effective at Kinast. One operator can fill approx. 20 m³ in 1.5 to 2 hours using a single crane bucket.

Numerous applications

Battery units can be used to produce virtually all types of flat precast concrete elements required for the construction of, for example, residential and social buildings or schools (but no three-dimensional precast elements such as staircases).

These include load-bearing and non-load-bearing interior walls, exterior walls (including insulated walls, test report available), loggia slabs using special bulkhead walls, solid slabs and insulated roof slabs.

Gerd Kinast concludes: “We literally started from scratch 25 years ago – you know from own experience how difficult many things were in the new German states at the time. But we have successfully overcome all obstacles, and in the foreseeable future I will hand over control of the business to my daughter-in-law, Kerstin Kinast.”

CONTACT

Kinast Maschinensysteme GmbH

Alexander-Monski-Str. 9

04838 Eilenburg/Germany

+49 3423 7001-6