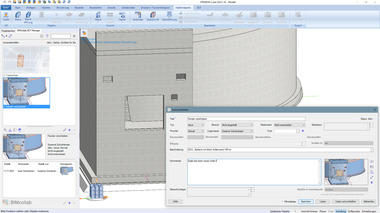

A new Allplan Precast module offers striking benefits

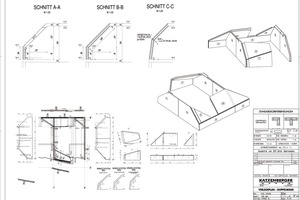

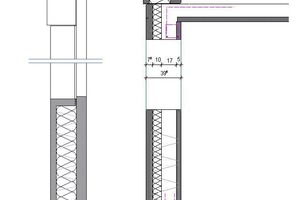

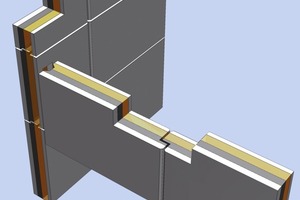

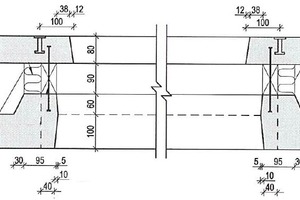

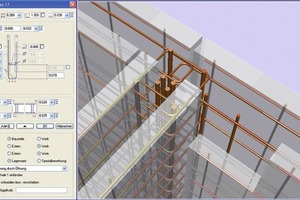

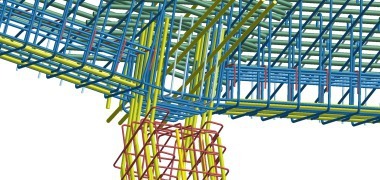

With today’s state-of-the-art software, it is very easy and efficient to design a double wall. However, dozens of man-years of development work have been invested in the dedicated programs, which provide a correspondingly wide range of features. The design exercise will become much more demanding, though, if inclined walls need to be planned, a core insulation is to be included, or various wall thicknesses need to be incorporated in a single shell. In addition, customers wish to receive high-quality plans, drawings and bills of materials from a single source.

This requirement easily prolongs the planning period

required.

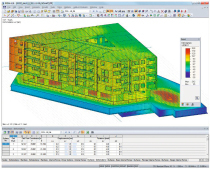

oday, the requirements on a state-of-the-art program can be summarized as follows: provide production data for machinery; integrate a complete materials management system; create invoicing data in accordance with specific invoicing rules; provide clear and legible production schedules; provide element definition of the model.

As far as possible, all these features should be automated or executable at the push of a button.

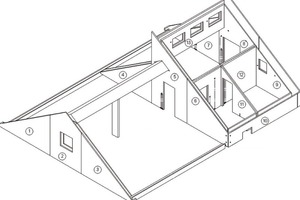

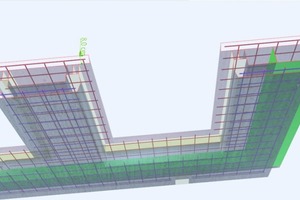

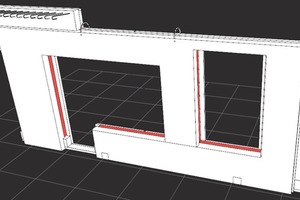

The design drawn up by the architect is used as a basis to implement these client requirements. This design is transferred to a plan or precast component model in a manner...