Green concretes with limestone powder

On a global scale, concrete and cement production accounts for more than 6 % of anthropogenic CO2 emissions. Substitution of the cement clinker (K) contained in the cement or concrete by appropriate alternative materials can thus significantly reduce the global warming potential. Owing to their commercial, technical and environmental benefits, blast-furnace slag and hard-coal fly ash are currently used as the main alternative cement constituents or concrete admixtures in Germany. However, these materials are available only in limited quantities, which is why it is not possible to considerably increase their use in the German cement and concrete industries. Furthermore, it should be noted that fly ash will no longer be available in sufficient amounts in the medium to long term because power generation from hard coal will be largely phased out.

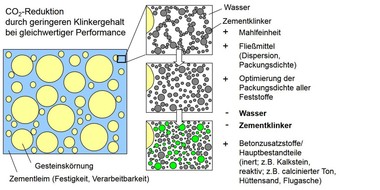

Alternative materials primarily include calcined clays and limestone powder, which can be added as a main cement constituent or concrete additive. The pozzolanic effect of calcined clay is achieved by firing suitable varieties of clay. However, the production process is relatively complex in terms of the related technology whilst also consuming a large amount of energy. Limestone powder is readily available at a very low cost because it involves just a single processing step, i.e. grinding. Its involvement in the hydration processes within the cement paste is negligible, which is why the use of limestone powder may require certain concrete technology modifications. Furthermore, ground limestone (LL) can currently replace cement clinker (K) only to a very limited extent due to the restrictive nature of applicable codes and standards as well as approval procedures.

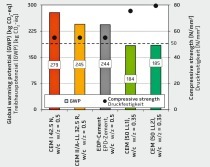

A number of research projects found that concretes to which limestone-rich cements with a limestone content of up to 50 wt.-% are added can reach at least identical levels of strength and durability compared to concrete mixes designed on the basis of the descriptive rules specified in DIN 1045-2 [1]. This modification reduces CO2 emissions by up to 25 % compared to the reference mix containing the average German cement grade (EPD cement). Using such binder systems in practice will require adjustment of process engineering parameters at the cement plant as well as of the related concrete technology variables, particularly a reduced w/c ratio [2].

Combining limestone powder (LL) with reactive substitutes, such as blast-furnace slag (S) or calcined clay, appears to be a promising approach to producing exceedingly durable precast concrete components with a low environmental impact. This method also enables very efficient utilization of these materials. At common w/c ratios, the use of multi-composite cements with slag and limestone with a clinker content of about 50 wt.-% proved to be very promising (Fig.) because the global warming potential of these concrete mixes was reduced by about 35 % [3]. Multi-composite cements with a clinker content of 35 or 20 wt.-% make it possible to mitigate environmental impact by up to 40 % and 55 %, respectively. However, this would also require lowering of the water/cement ratio compared to the reference mixes or thresholds specified in relevant codes and standards (see Fig.).

![Global warming potential [kg CO2 equiv] and compression strength [N/mm²] of studied concretes with different cement compositions and w/c-ratios](https://www.bft-international.com/imgs/1/3/9/7/0/9/0/tok_c45fee743dff206a80711f4af16efe5a/w300_h200_x600_y341_1_4_Rezvani_Abb-a67d8c0451c592cd.jpeg)