Strategic implementations for practitioners

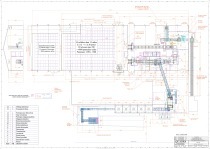

Over a period of four years (2015 to 2019), one of the two production lines was replaced in several construction sections of different sizes. Particular attention was paid to the fact that the best available technology was used everywhere. Moreover, for the first time in the world, the sorting system has completely been replaced by a sorting robot of Kuka. This allows for complete digitalization: The Hess concrete block machine creates layer IDs, which the machine transfers via the connected PLC control system to the dry side at Rekers through to the cubing system. After cubing the layer IDs are converted into a package ID, which are affixed to the packages by means of a label printer. These IDs enable tracing back all data from the production – e.g., regarding the mix design, machine settings of the concrete block machine, any blocks replaced by the robot or the reasons of individual machine failures. This system allows for checking and optimizing the machine settings faster and in a more professional manner. In parallel, the already outdated product management system on the basis of MS DOS was upgraded by a completely new industry-specific software of the Softbauware provider. Along with the processes in the field of administration, such as selling of products, the software is now also used for mold management and the production planning of precast elements as well as the two concrete block machines. Kortmann Beton is known throughout Germany for customized solutions and concrete pavements for use in the area of WHG (German Water Resource Law), precast elements for use in civil engineering and paving blocks.