Post-installed wedge anchor for dynamic loads

The BZ3 Dynamic wedge anchor, according to the manufacturer, is the first mechanical expansion anchor with a European Technical Assessment (ETA) for fatigue loading (Fig. 1).

The ETA-20/0117 also includes seismic approval for earthquake loading. The BZ3 Dynamic wedge anchor can be quickly installed and immediately loaded. This makes it a cost-efficient alternative to injection systems and undercut anchors. Typical applications are fastenings of elevator guides, craneways, noise-protection walls, tunnel equipment as well as fastenings of industrial robots and bridge superstructures.

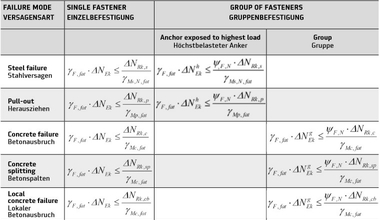

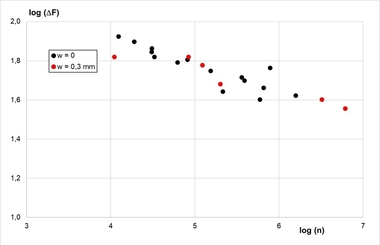

The hole clearance between attachment and anchor is not only harmful when subjected to earthquake loading as: the so-called hammer effect increases the action load demand. Under fatigue loading with many hundreds of thousands of load cycles, it is critical to prevent any hole clearance, in order to enable the design of the fastening and to prevent early failure.

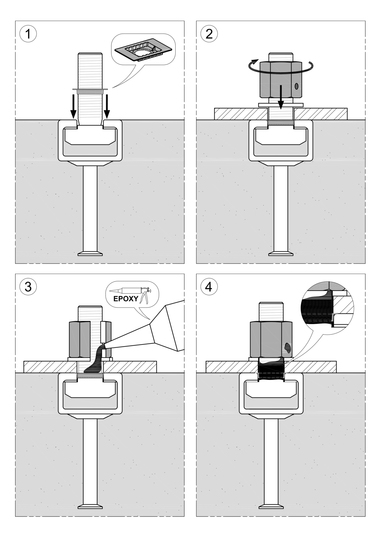

In order to eliminate the hole clearance required for compensating tolerances during installation works, it is necessary to fill the annular gap between attachment and anchor. Special filling washers are used here. The filling washers are provided with boreholes through which, following installation, a high-strength mortar is injected. The hardened mortar permanently and reliably prevents lateral movements of the attachment.

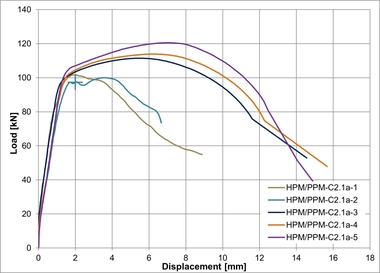

Wedge anchors as fastening solution for dynamic loads

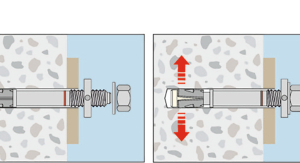

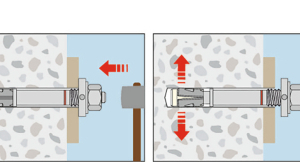

The BZ3 Dynamic wedge anchor is available in the sizes M10, M12 and M16. It is suitable not only suitable for preset-installations where the anchor is installed before the attachment is mounted (Fig. 2). But it is also suitable for through-installations where the anchor is installed through the already positioned attachment (Fig. 3). Following these steps, only the defined installation torque must be applied, the safety nut thrown over and the two-component mortar injected by means of the mixer reduction.

The simple and cost-effective application of the BZ3 Dynamic wedge anchor has already been proven in many projects, such as for the S21 Filder Tunnel, where many kilometers of equipment were installed (Fig. 4). Fatigue capacity is certified separately for every batch of material by fatigue testing on the installed wedge anchor to ensure that the high demands during dynamic loading are met safely.

CONTACT

MKT Metall-Kunststoff-Technik

GmbH & Co.KG

Auf dem Immel 2

67685 Weilerbach/Germany

+49 6374 9116-0