Basotect sound absorbers in thermoactive prefabricated concrete ceilings

When a thermoactive element is incorporated into a concrete ceiling, this is offset by part of the building itself to regulate heat. This technology produces extremely energy-efficient cooling and heating in modern buildings that in some cases can make them eligible for passive house certification. Typically, though, the drawback is that the sound-reflecting surfaces of a concrete ceiling mean poorer room acoustics due to longer reverberation times. When acoustic absorbers are subsequently fitted for sound insulation, however, they often have an adverse effect on the convection of air needed, which then considerably reduces the efficiency of the cooling and heating capacity.

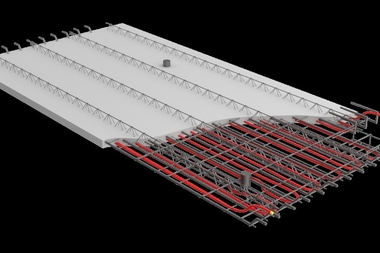

The innovative Ceiltec thermoactive prefabricated concrete ceilings from Innogration GmbH counter this challenge by using BASF’s Basotect sound-insulating melamine resin foam.

Easy to install

The integration of Basotect in the recesses of the Ceiltec prefabricated ceiling gives the thermoactive concrete ceiling outstanding multifunctionality with, at the same time, excellent acoustic properties. Even a small coverage of the ceiling (e.g. 10 to 15 %) produces a significant reduction in the reverberation time in the room.

Basotect is a very versatile foam, and its high sound absorption capacity not only creates a pleasant acoustic experience but because it is non-flammable, it is also an important material for the fire protection in modern buildings. In addition to this, because it has an extremely low density and does not contain mineral fiber, Basotect is very easy to install in the recesses provided in concrete ceilings.

“The demand for multifunctional structural elements providing both a good indoor climate and improved room acoustics is steadily growing”, explains Thomas Friedrich, CEO of Innogration GmbH. “The integrated Basotect strip absorbers in the prefabricated Ceiltec ceiling mean that the system offers a holistic solution – heating and cooling with the concrete surface but also effective sound absorption on the otherwise sound-reflecting underside of the ceiling.”

Architects impressed

Innogration GmbH has already fitted a number of office and administration buildings in Austria, Germany and Switzerland with Ceiltec concrete prefabricated ceilings, including the Smarthouse in Munich, the Kreativpark office building in Karlsruhe and the Institut Heidger in Osann-Monzel an der Mosel. It is in the Institute Hediger where Innogration held a joint workshop with BASF in October 2015, titled “Cooling, heating and acoustics in the modern office world”. This provided an opportunity to discuss the challenges faced today by component-activated buildings and offered practical solution concepts for acoustic design. The ultimate highlight of the presentation was a hands-on opportunity for architects and planners to experience for themselves the attractive room acoustics in the office and laboratory areas.

“Innogration GmbH’s Ceiltec thermoactive prefabricated concrete ceilings fitted with Basotect embody a new trend in the modern office environment and are an example of how the high requirements on energy efficiency, acoustics and design can be met”, commented Dr. Normen Langner, Bilfinger Bauperformance GmbH, in summing up the successful day.

Basotect foam has a unique range of properties. Its base material makes it flame-retardant and abrasive; it can be used at up to 240 °C and retains its properties over a wide temperature range. Because of its open-cell foam structure, it is light, sound-absorbing, flexible even at low temperatures and thermally insulating.